Glassmaking has seen evolution over the years since it was first discovered milenniums ago. Cutting glass in our day is a very technical job that must be done using specialized tools and machinery and it is pretty tiring. These are all the essential tools due to their role in cutting glass into shapes and sizes in coming up with whatever it is that we find useful for life-like windows mirrors, and lenses for glasses. GLASINO is a company that offers most of these tools.

Most Useful Tools for Cutting Glass

It is one of the most useful cutters for cutting glass: it is the diamond cutter. Special shapes and sizes of laminated glass cutting machine are supplied to meet diverse cutting requirements. Diamond cutters have edges coated with a thin layer of diamond dust which makes them very resistant and supports the accuracy of cutting the glass.

Machines for Cutting Glass

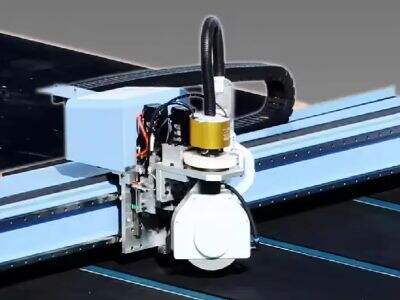

However, in this present moment, machines are an essential part of glass makers today now living in glass-making factories to help glass makers meet the ever-rising demand for glass objects with high quality. Computer Numeric Control machines are one of the most important machine types. These glass cutting equipment are used for precise and fast cutting/breaking of the glass. Since they are programmed to control the cutting tools they ensure that the cuts are always done the same way. This degree of precision ensures the glass gets the perfect cut resulting in better products than people cutting the glass manually.

QA Solutions for Glass Manufacturers

Glass cutting is a delicate service that requires high-precision tooling and machinery. The very minimum equipment for glass works are glass cutting, grinding, and polishing machines. Glass cutters are very important because they can draw a line on the glass surface which can break the glass along that drawn line. Diamond-dusted grinding wheels are used for polishing the edges of cut glass. This is really necessary in order to make sure that it is safe to touch the glass. Finally, a few polishing machines are used in applying a glossy and transparent surface to the glass hence bettering its visual appearance and quality.

Emerging Technology in Glass Cutting

Glass cutting and manufacture is one product that will always have a demand. New technology has allowed glass manufacturers to create new products that are more accurate than ever. Waterjet cutting is one of the relatively new and exciting techniques of cutting and shaping of glass. It is performed by using water at extremely high pressure to cut the glass, leaving a glass edge when done. As glass cutting line has high precision with really low breakage, waste (both environment-friendly and production defect), it is being used to replace the earlier glass cut methods.

Glass Making Tools – Regular Tools for Glass

With the upgrade of technology it is unavoidable to have new tools or equipment to fast and easy glass production. To survive in today's market, glass makers must be armed with the newest and best instruments. An example here is glass cutting tables which are made specifically to cut and do some processing for glasses. They hold the glass not to break due to being flat and smooth in addition to the edge that makes a cut for the glass.

EN

EN

AR

AR

FR

FR

DE

DE

PT

PT

RU

RU

ES

ES