Laminated glass is a type of safety glass that can be seen everywhere in our daily life, including windows, doors and car windscreen. It is formed by sandwiching two or more layers of glass together and held in place with a plastic layer inserted between. Laminated Glass can be stronger and less likely to break than normal glass. For this reason, many individuals have turned to laminated glass for their own projects and requirements.

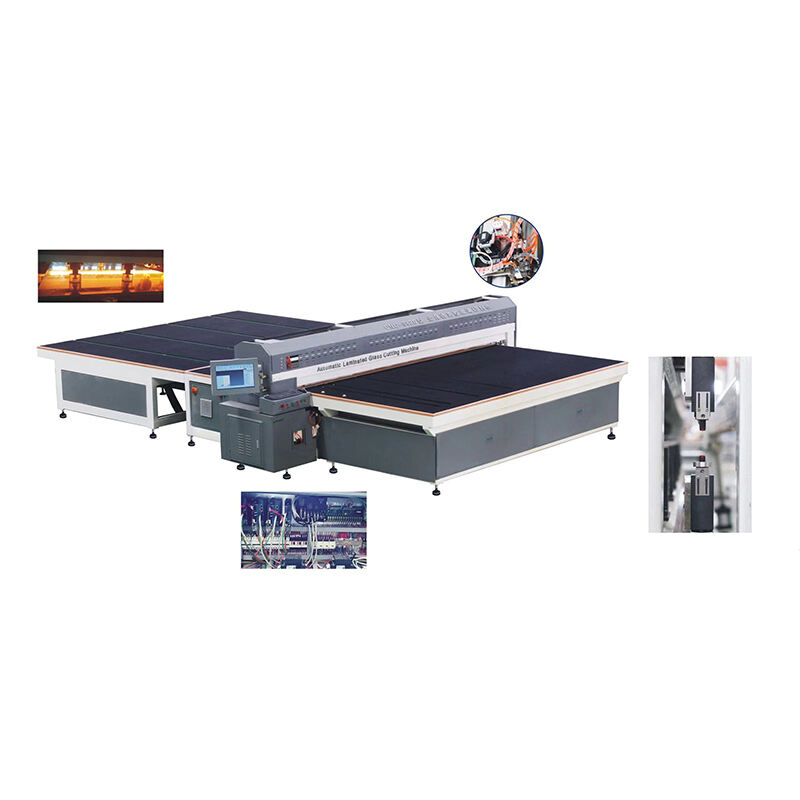

Laminated glass is difficult to cut, especially with a normal glass cutting tool. Many layers of glass and plastic in use here, normal tools may not have a very high success ratio. However, with a good laminated cutting machine you can get it perfect every time. These machines are designed to cut laminated glass quickly and easily requires you a single time so neither your work is hindered nor the hands.

This is done with the use of special blades in laminated glass cutting machines which are manufactured to slice this untempered plastic as they pass through the layers. Its breaking feature is highly effective in enabling you to cleanly break cut the glass, without damaging either the plastic layer or even other cells. In no time, you will use a laminated glass cutting machine such as a professional to cut the tempered layer!

However, cutting laminated glass is risky due to the fact normal tools that use for regular cuts in glass. The glass can even shatter causing a severe injury when the plastic layer sandwiched between glasses expand so somewhere somehow, the tempered screen protector first few layerls may get cracked or breaking. When you cut glass, of course you these rules apply.

Precision Laminated glass cutting machines are both safe and accurate. These utilize unique blades which are created to cut each layers of the glass at a time without breaking or harming them (). Moreover, these devices include security measures to safeguard the one who uses that device from any damage.

These devices are built with unique blades to enable the production of clean, burr-free cuts. This allows you to bevel the 45-degree edge before it is cut, and without having to sand or smooth after cutting. Since you are the professional start looking like it!!!!!

To sum up, the laminated glass cutting machine is a fairly useful device to obtain, for by just about anyone that works with this type of specific kind of cup. They are very handy for rapid and efficient glass slicing of this kind, they´ve a variety of uses throughout the trades.

laminated glass cutting machine factory enjoys the benefit of economies of scale due to the introduction of cutting-edge production equipment and technology Manual work is reduced Furthermore the speed of production with high-efficiency equipment tends to be faster which will quickly complete the manufacturing task and improve the production speed and efficiency

In laminated glass cutting machine to reduce the number of products that are defective, and to improve customer satisfaction, strict quality inspections are performed. A solid quality control system in place to ensure continuous quality control. Improve inspection and testing methods

laminated glass cutting machine accordance with the market condition the factory can adjust the production plan according to the market conditions in order to keep up with changing market demand and maintain an advantage in the market. Create flexible production lines, and use information technology to meet the demand of the market. Modify production plans according to the basis of time.

The company is focusing on innovation in production technology Create new technologies and innovating with the laminated glass cutting machine of the existing technology Improve the manufacturing technology of the product more efficient Keep your product competitive on the market