I. Structure Features:

1.1 The machine structure is aluminum alloy assembled structure, never scrap, with permanent service life, and can save 70% energy.

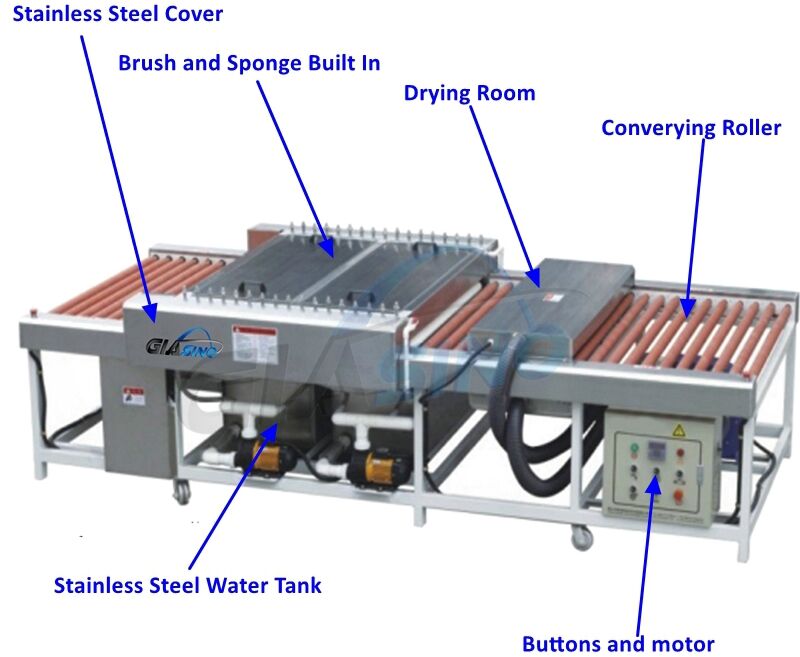

1.2 Washing section and panels contact with water are stainless steel.

1.3 Metal panels of other parts are painted with top-grade machine paint or powder.

1.4 All transmitting rubber rollers of the machine are velcanized rubber with SS304 shaft(They are forbidden to contact with acidic liquids.)

1.5 Washing section and drying section can be risen up max.to 350mm as a whole, which is convenient to wash and maintain.

1.6 The machine has three pairs of brushes (φ160mm) with SS304 shaft.( Washing LOW-E glass function is optional: can wash LOW-E glass, ordinary coated and solar coated glass without any scratch on surface).

1.7 The machine has two pairs of air knife which has large wind and good drying effect. The machine has air heating system.

1.8 Blower has air filter in air inlet, big airflow and excellent drying effec. The whole blower is installed on the top of machine to save space and it can be risen up with washing and drying section together, and the air filter is on the side for coveninent inspection and cleaning.

1.9 Main drive is gear drive, inverter speed control and digital display. Brush roller drive of washing section is drove by upper and lower motors with separate belts, which has smooth speed and long service life and can wash special glass which need high quality clearance.

1.10 The machine is control by mechanical button and with digital display, which is convenient of workers operation. it’s the best choice for saving labor if connect with other machine.

1.11 Water tanks of machine are movable, which is easy for cleaning , changing water, checking, etc., and make washing effect better.

II. Technical Parameters:

2.1 Max.Glass Size: 2500mm

2.2 Min.Glass Size:400mm*400mm(limit to put glass from left and right sides in single row)

2.3 Glass Thickness:3mm-25mm(digital display)

2.4 Speed Range: Vmax=1-12m/min(glass thickness within 3-25mm)

1

2.5 Rubber Roller and Brush Roller Speed: adjusted by inverter

2.6 Working Height: 900mm

2.7 Total Power: 32KW

2.8 Water Source: circulating water,city water, and deionized water ( Buyers need to prepare deionized water equipment by themselves. )

2.9 Power Supply: 380V 50Hz

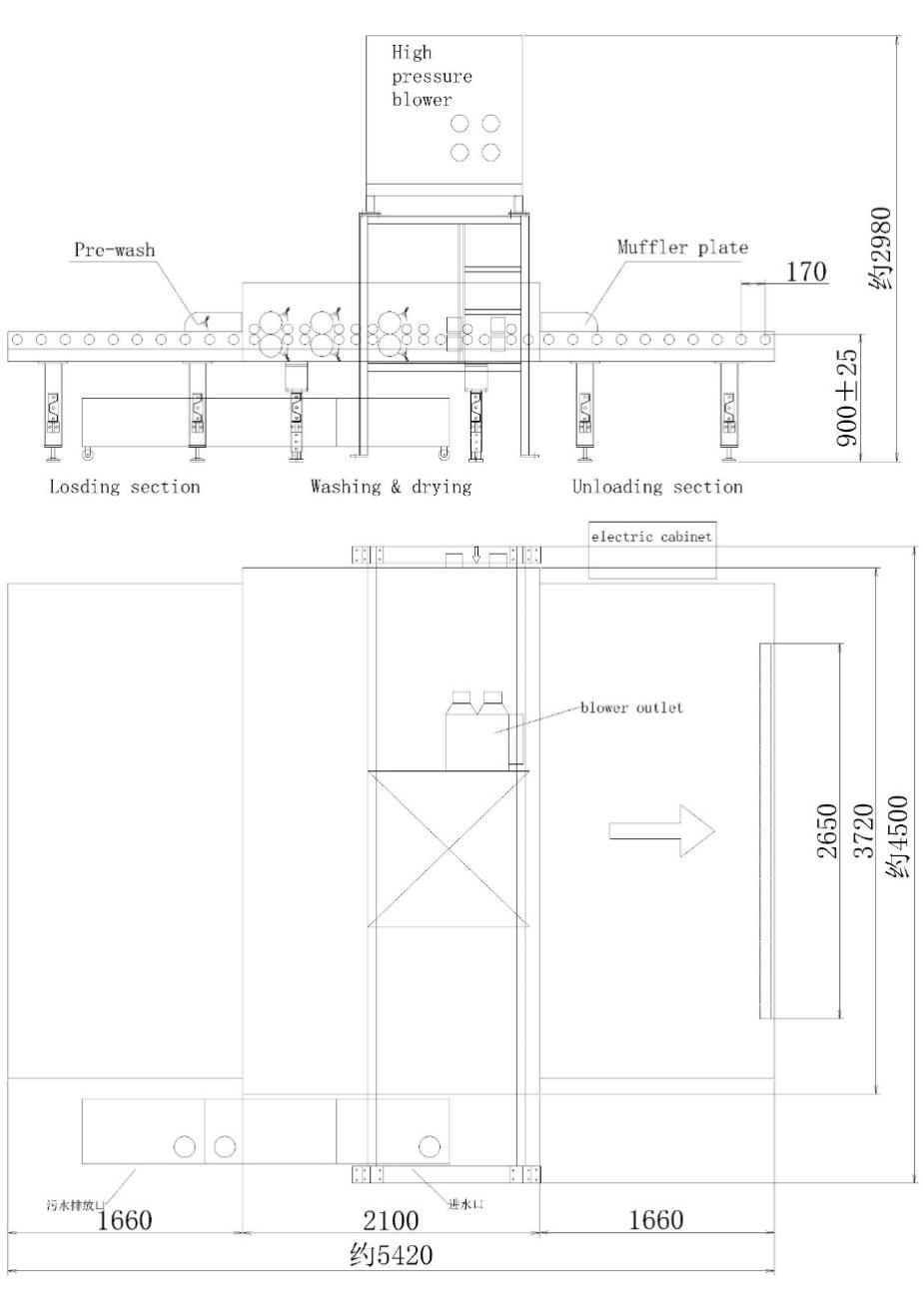

2.10 Machine Dimension: 5500*4500*2840mm(L*W*H)

2.11 Machine Weight: 3840KG

2

III. Main Configuration

3.1 Main Drive Motor: XingGuang|Zhejiang XinLing

3.2 Brush Motor: Zhejiang XinLing

3.3 High-pressure Blower: Guangdong TaiWei

3.4 Water Pump: Guangdong LX

3.5 Inverter: Taiwan DELTA

3.6 Metal plater cotacted with water and air knife are stainless steel: Guangdong Foshan

3.7Stainless steel water tanks and cover: Guangdong Foshan

3.8 Transmission Rubber Roller: Foshan Yingjun or Shengchang

3.9 Main electric Components in Control Cabinet: Schneider

IV. Layout:

Machine Detail Picture Reference

Packing & Delivery

Company Profile

Jinan Glasino Machinery Co.,Ltd founded in 2003, is the high-tech enterprises specializing in the production of Glass tempering furnace CNC glass cutting machine, insulating glass machine, curtain wall glass machine, market share ranks first in the same line. Main products are: Laminated glass cutting machine, Automatic glass Cutting line, Multifunctional glass cutting machine, Insulating glass production line, Automatic insulating glass CNC sealing machine, Aluminum spacer bending machine, Desiccant filling machine etc, full set processing machines for insulating glass. We have passed European CE certificate, Switzerland SGS certificate ,ISO 9001: 2008 quality control system, win good reputation from domestic and international customers. Outstanding quality is the basis of brand. Satisfying service is the guarantee or brand. Perpetual innovation is the soul of brand. Glasino people will continue making efforts and persist in taking the quality as the life of the enterprise. Continuously improve the production management level, research and develop more advanced technology to meet the needs of the market. Glasino will work with you to create a brilliant future.

Exihibition

We participated in exhibitions all over the world and established good relationships with customers.

Our friendly team would love to hear from you!