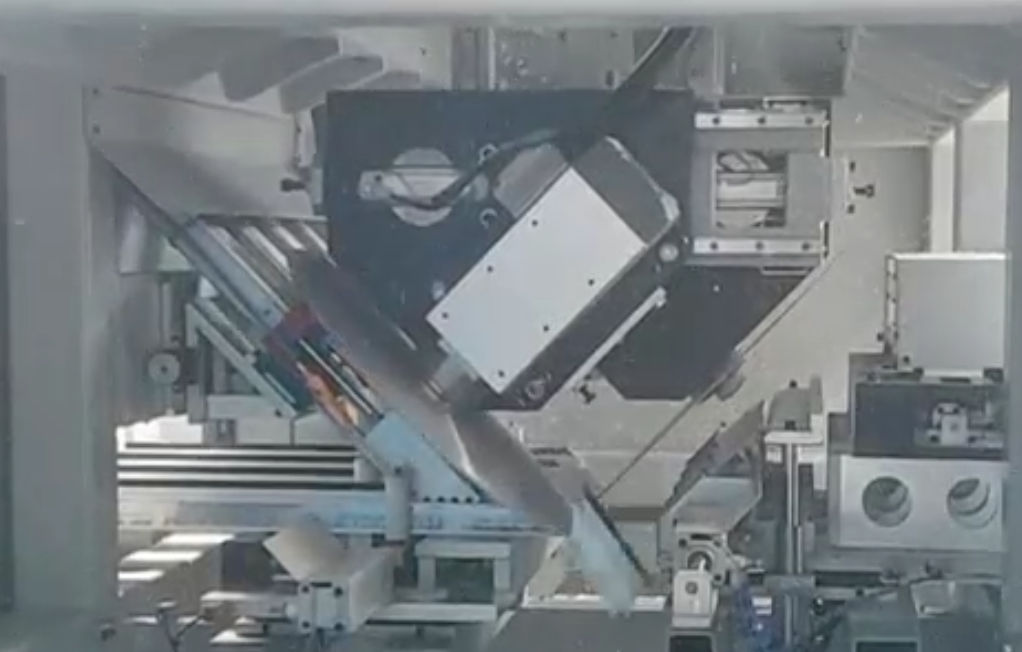

The sawing unit of the complex window system solution is used to automatically realize the fixed-length cutting of 45°, V-shaped mouth and middle stiles of plastic profiles. It is suitable for mass production of high-end doors and windows.

Product introduction

1.Automatically download optimized blanking data and process parameters without manual input and adjustment.

2.Automatically complete profile clamping, feeding and cutting, with a high degree of automation

3.Equipped with a circulating feeding system, which greatly improves the production efficiency

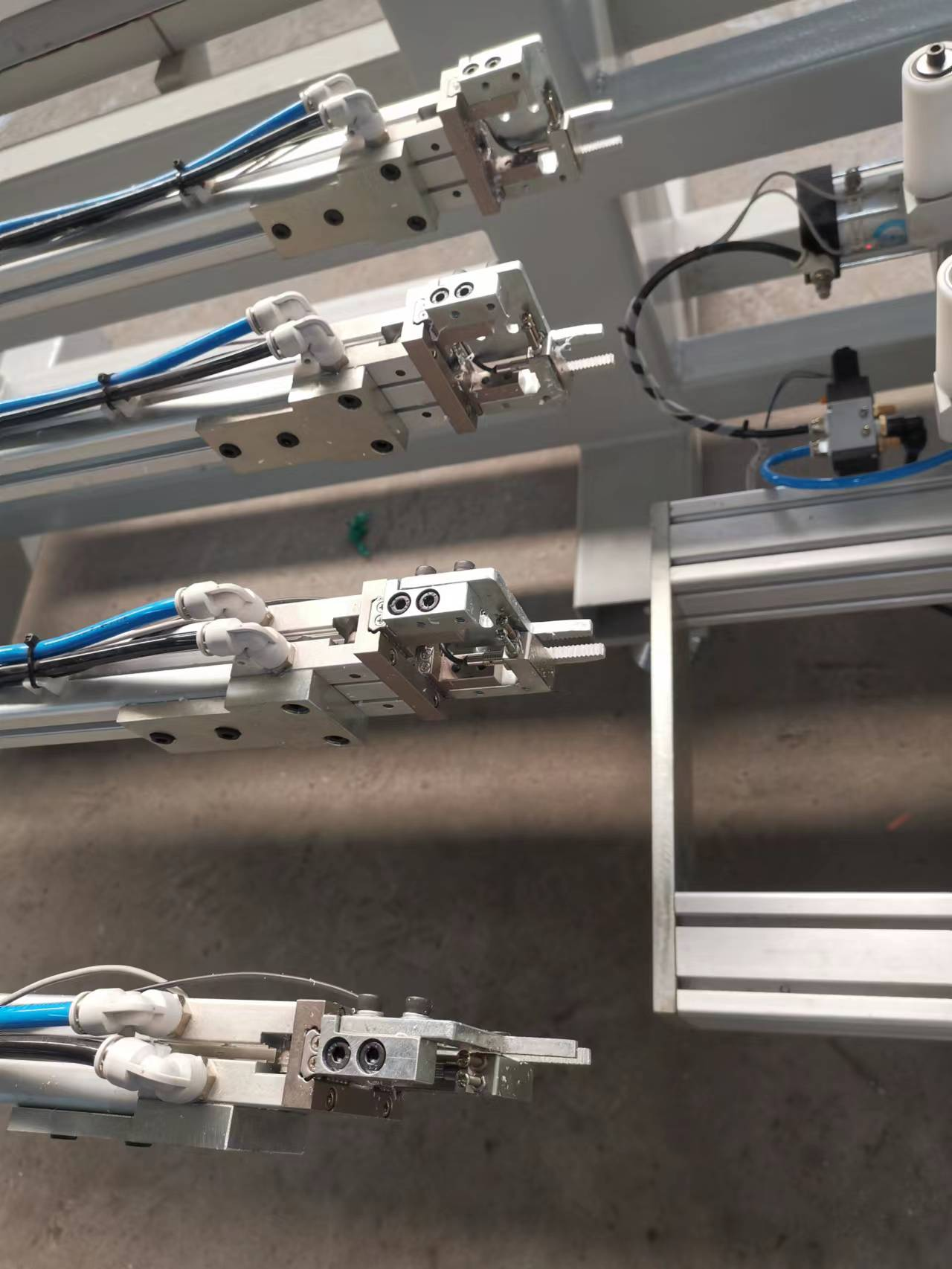

4.The manipulator can be clamped at the same time to complete the sawing of four profiles at one time, with high production efficiency

5.High-speed feeding system, high production efficiency

6.High-precision spindle motor, high processing quality

7.Linear motion pair guide rail, high dimensional accuracy of processed products

8.Three-axis CNC, high degree of automation

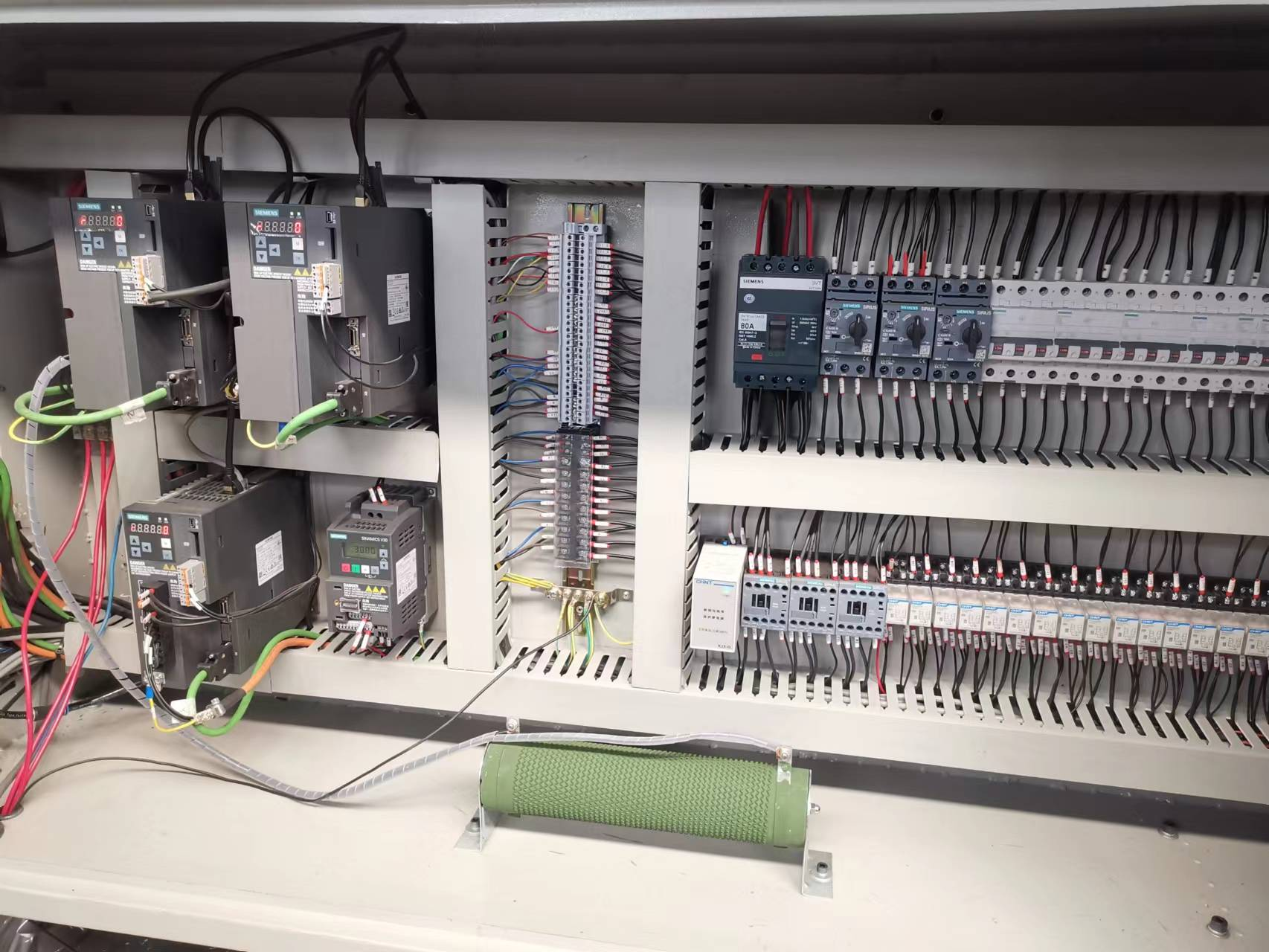

9.Imported drive system with high machining accuracy

10.All imported high-quality electrical and pneumatic system components are used, with high stability and reliability

11.It can communicate with the host computer, automatically select processing tasks, and flexibly realize computer-aided design/manufacturing (CAD/CAM)

Main Features

1.Configurable barcode printer, print material identification in real time, realize process information identification, and facilitate material management (software support).

2.Equipped with automatic discharge system, simple and convenient operation.

3.With automatic material head collection system, the working environment is clean and tidy.

4.The height design of the operating table and the fuselage conforms to the ergonomic principle, reducing the labor intensity of workers.

5.17-inch large control screen with graphic interface, simple and intuitive operation.

This machine is especially suitable for the production of complex window shapes in batches and high quality.

The main technical parameters

|

Working Voltage |

380V 50Hz 3 phase |

|

Input power |

10.5Kw |

|

Saw blade speed |

3000r/min |

|

Saw blade specification |

Φ500×4.3×Φ30mm(outer diameter×saw thickness×inner hole) |

|

Processing profile length range |

max 6000mm, according to user needs |

|

Cutting width |

max 150 (single) |

|

Cutting height

|

Frame fan profile: ≤120mm Mullion profile: 54~120mm V-port depth: ≤60mm |

|

Minimum cutting length

|

frame fan profile: 330mm Mullion profile: 330mm |

|

Working air pressure |

0.5~0.8MPa |

|

Air consumption |

330L/Min |

|

Dimensions |

11900×4400×2400(mm)(L×W×H) |

|

Weight |

3900Kg |

|

Controller |

Siemens, Germany |

|

Driver and motors |

Siemens, Germany |

|

Low voltage electrical appliances |

Siemens, Germany |

|

Saw motors |

Seimec, Italy |

|

Saw Blade |

Hirono, Japan |

|

Liner Guide Rail |

Taiwan, China |

|

Air Cylinder |

AirTac, Taiwan, China. |

|

The electromagnetic valve |

EMC |

|

proximity switch |

Omron |

More pictures:

|

|

|

|

|

|

Our friendly team would love to hear from you!