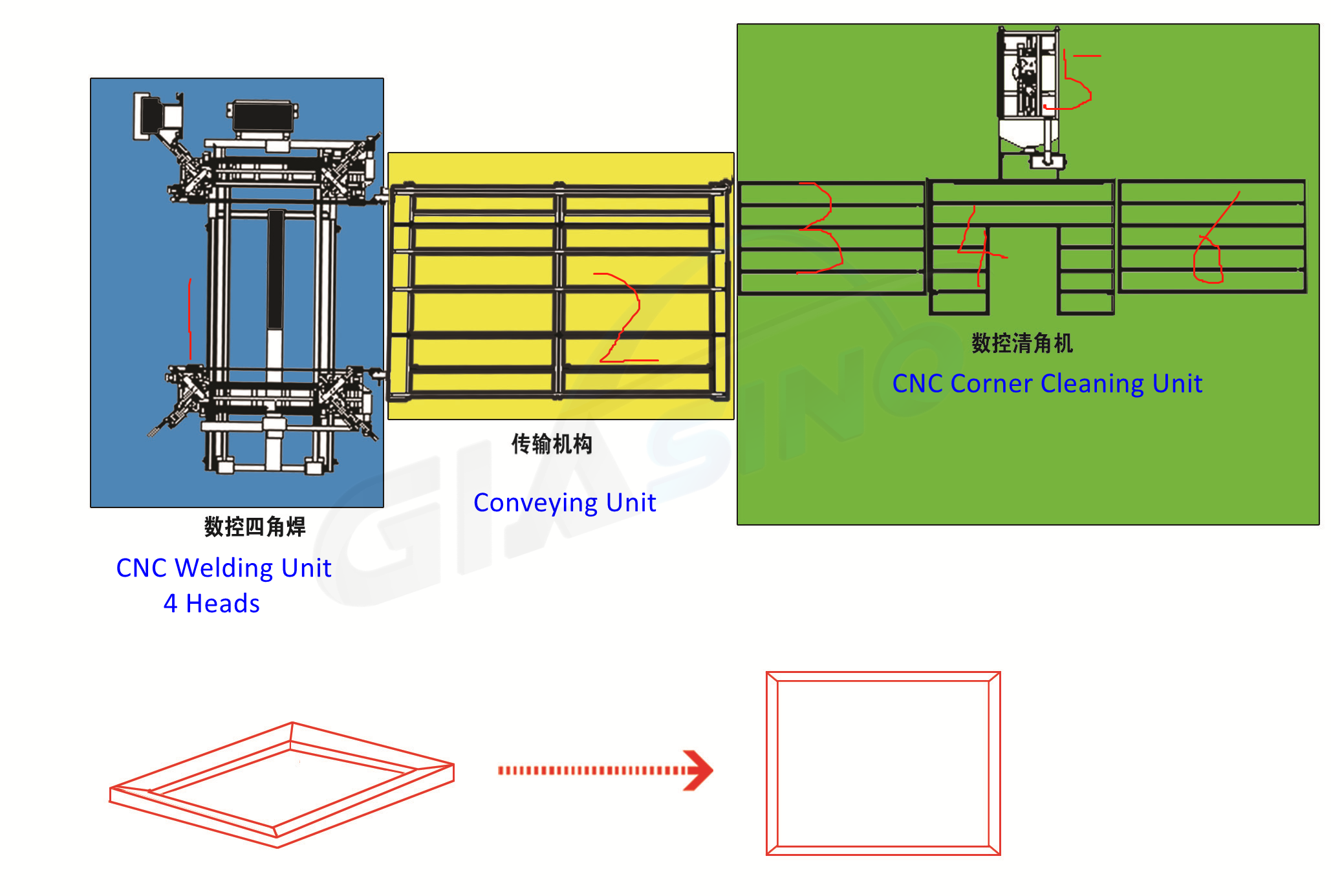

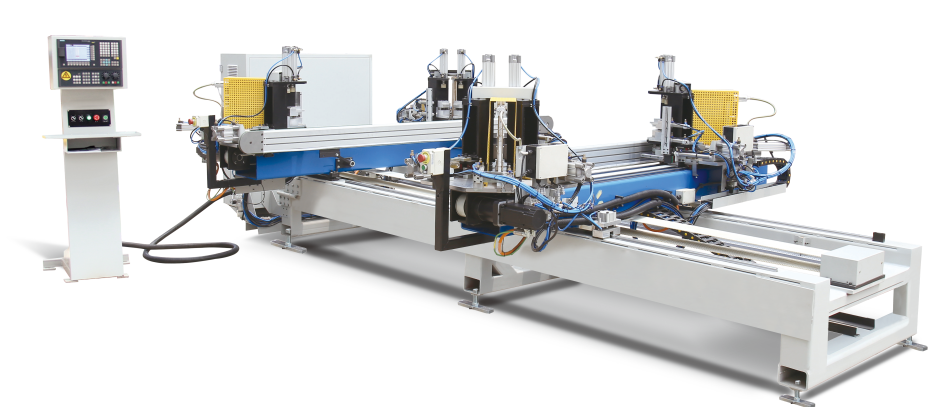

PVC CNC horizontal four-corner welding machine (SHP4W-CNC-3000A)

Equipment Advantages

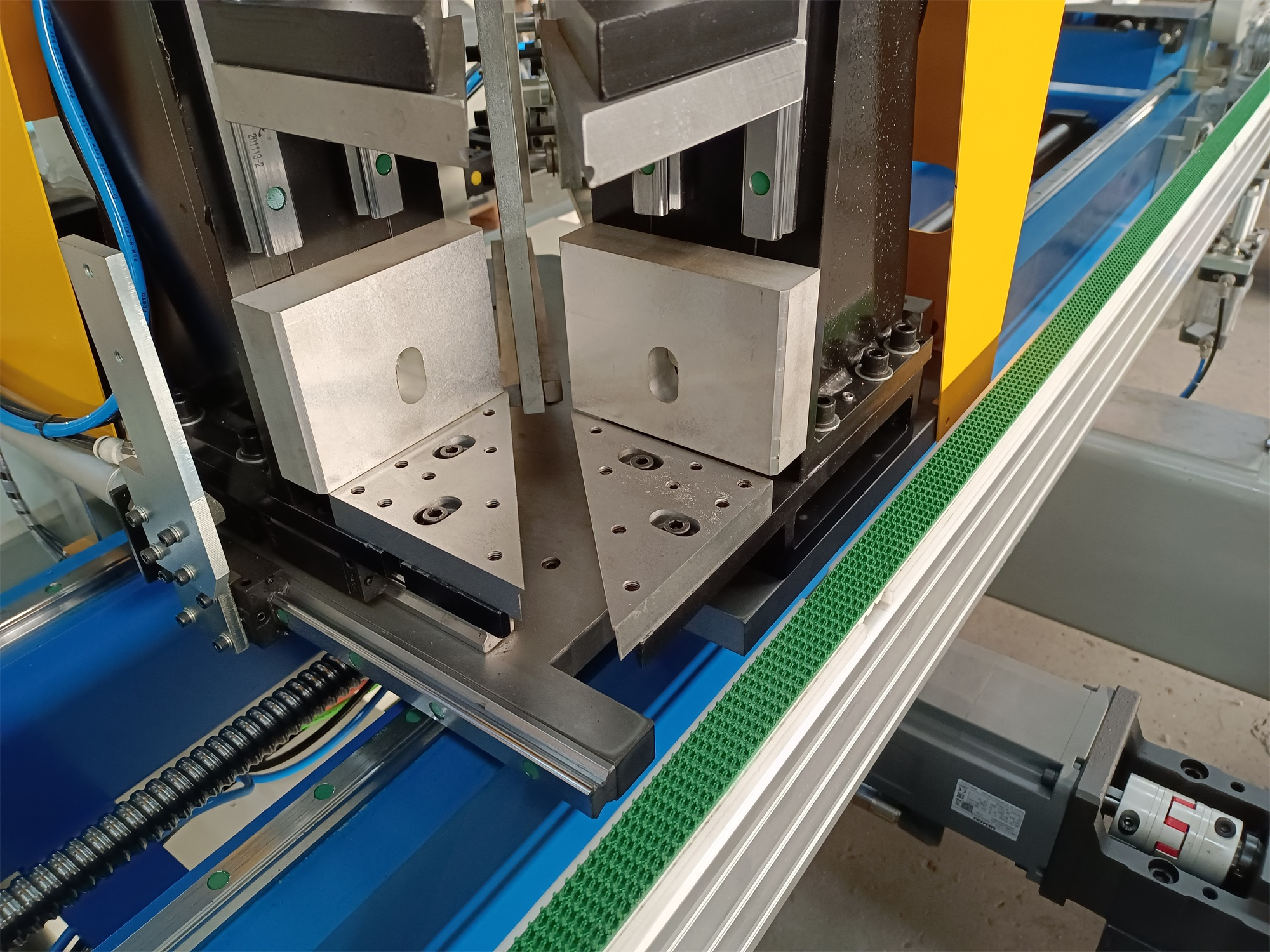

1.The X, Y, and Z axes of the whole machine are all driven by high-precision roller screws

The fuselage is arranged horizontally and adopts enhanced rigidity design, which is stable and reliable

2.The unique super-rigid design of the machine head can truly meet the strength requirements of the welding angle

3.All feeding adopts square guide rail kinematic pairs, stable and reliable performance

The unique know-how (technical know-how) improves the weld angle strength and quality of products

4.The welding backing plate can be replaced quickly and conveniently, and the door and window products are of high grade

5.It adopts a complete set of imported brand numerical control system and high-quality electrical and pneumatic systems, with reliable performance

6.Optimized program design, high production efficiency

7.The special discharge mechanism realizes automatic discharge and reduces the labor intensity of workers

8.It can be conveniently used in in-line production to form an automatic line for welding and clearing corners

Main technical parameters

|

Name |

Parameters |

|

Voltage |

AC380V/50HZ Three-phase four-wire |

|

Working pressure |

0.5~0.8MPa |

|

Air consumption |

100L/min |

|

Working environment |

CNC Controller:-5℃~60℃ LCD screen:0℃~60℃ Pneumatic Components:-5℃~70℃ |

|

Total Power |

13.5KW |

|

Welding height |

20~165mm |

|

Welding width |

120mm |

|

Welding range |

400×450mm~2400×3000mm |

|

Overall dimension (L × w × h) |

5200×5000×1600(mm) |

|

Weight |

About 2000KG |

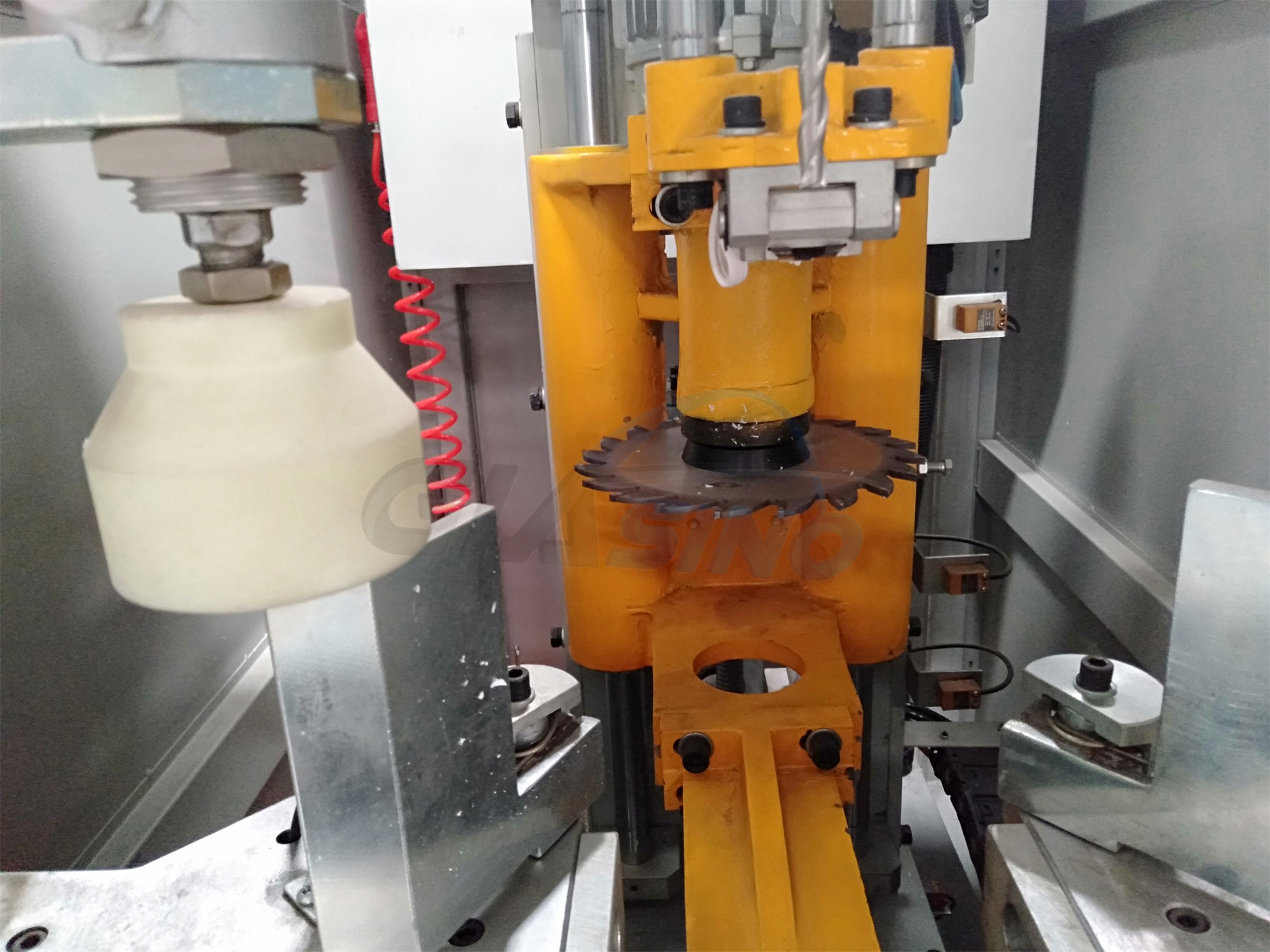

Pvc CNC corner cleaning machine (SQJA-CNC-120)

Pvc CNC corner cleaning machine (SQJA-CNC-120)

Function

Used for cleaning the welding corner joints of plastic doors and windows

Features

1.Two-axis CNC system

2.Servo drive system, numerical control system, solenoid valve, triplex and other main components are all imported brand-name products, with reliable performance and long service life

3.The unique internal positioning method ensures the accuracy of door and window weld seam cleaning

4.It can complete the cleaning of all kinds of profile welding angle facades, upper and lower plane welding seams, sealing strip grooves, etc., and can realize the processing of American-style profile lifting fan lock installation grooves at one time (optional)

5.Machining programs of various specifications and profiles can be stored

6.Achievable circular arc differential compensation and oblique line differential compensation, which can ideally meet the needs of making high-quality doors and windows with various cross-section profiles

7.Different cutting tools can be customized according to different profile sections to meet the angle-clearing requirements of different profiles

Main technical parameters

|

Voltage |

380v, 50hz |

|

working pressure |

0.5~0.8MPa |

|

Main milling cutter speed |

2880r/min |

|

Air consumption |

40L/min |

|

power |

1.4kW |

|

Processing profile width |

20~120mm |

|

Processing profile height |

30~130mm |

|

Dimensions |

1570mm×2670mm×2070mm |

|

Weight |

500kg |

|

|

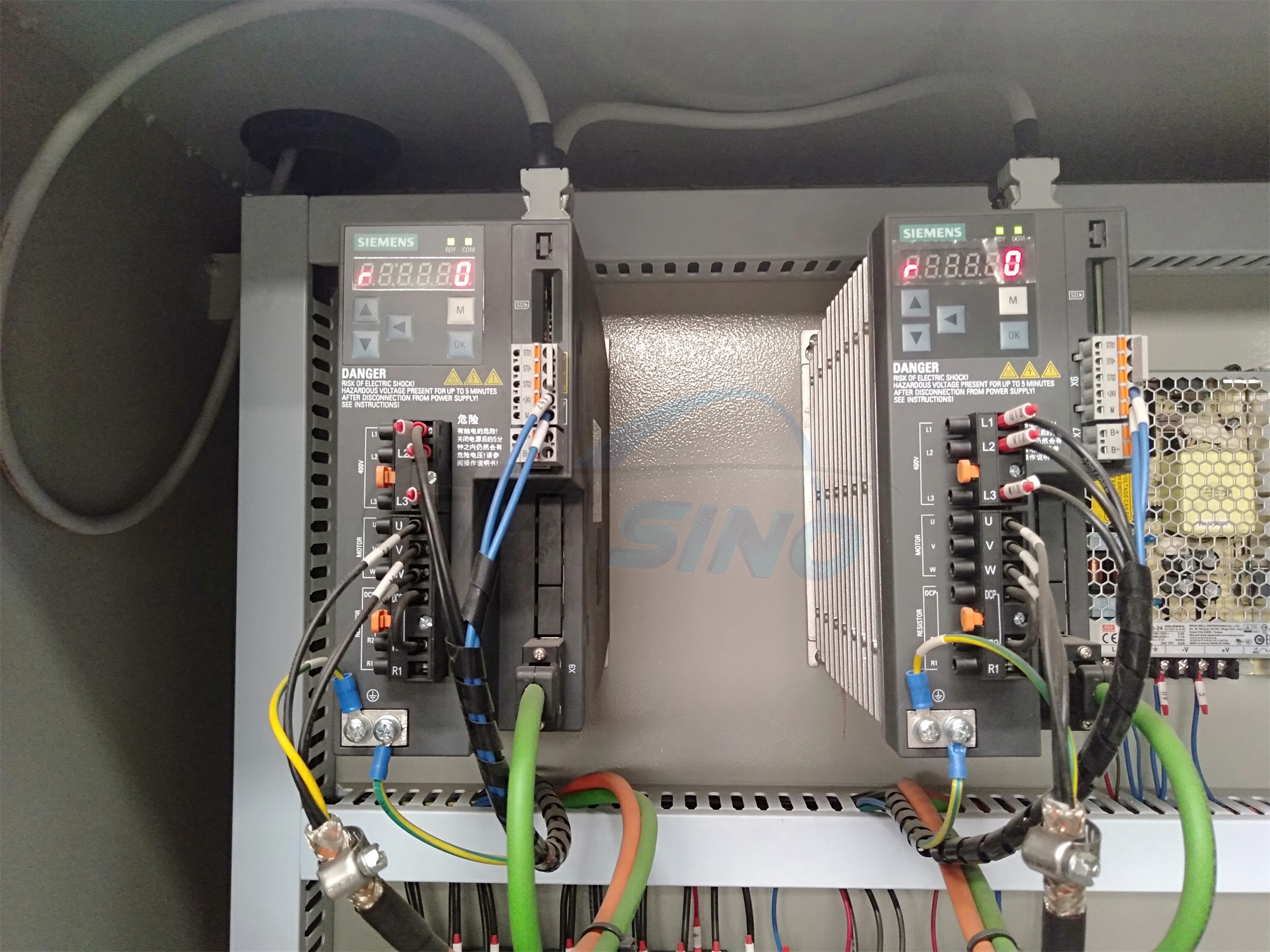

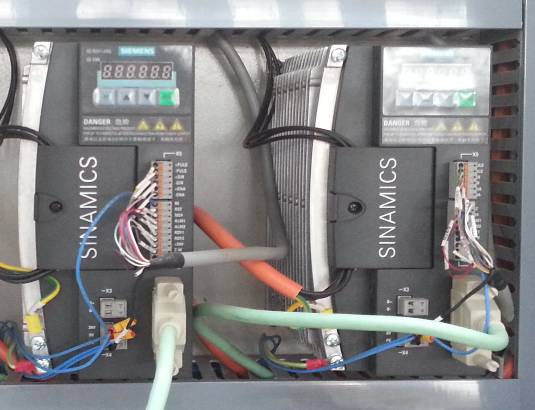

Main components and configuration

|

No. |

Parts Name |

Brand |

|

1 |

Low-voltage electrical apparatus |

Siemens(mostly), Germany |

|

2 |

PLC |

Siemens , Germany |

|

3 |

Servo motor and driver |

Siemens, Germany |

|

4 |

Button |

Yijia, China |

|

5 |

Proximity switch |

Omron, Japan |

|

6 |

Relay |

CHNIT/ Yudian, China |

|

8 |

Inverter |

Invoice, China |

|

9 |

cylinder |

AirTAC, Taiwan China |

|

10 |

Solenoid valve |

EMC, China |

|

11 |

Oil water separator (filter) |

EMC, China |

|

12 |

ball screw |

China |

|

13 |

Linear guide rail |

Hongli, China, not rusty |

|

14 |

Temperature control meter |

Yudian, China |

|

15 |

spindle |

Shenyi, China |

Rectangular automatic transfer table (SHQC-100)

Rectangular Workbench (STKA-2500)

C type workbench

More Pictures of machine:

|

|

|

|

Our friendly team would love to hear from you!