Main Features:

1. Opening and closing uses the servo and the double ball screw rod pair and the straight line guide rail pair, automatic opening and closing, the repetition localization is good;

2. The grinding head carriage adopts double dovetail guide rails, with stable operation and small vibration;

3. Polishing adopts high-precision cross ball guide, semi-automatic compensation or full-automatic compensation;

4. The upper 45 ° chamfer adopts automatic lifting, with accurate positioning and convenient operation;

5. that press frame can automatically rise and fall, the rising and fall range is large, and the replacement of the grinding wheel is convenient;

6. The main drive adopts double servo drive. Belt changing and maintenance are more convenient;

7. An annular synchronous belt and a pneumatic positioning device are adopted for glass conveying, so that the conveying is stable and the positioning is accurate;

8. a man-machine interface and a PLC high-end control system are adopt, that operation is simple and convenient, and the automation degree is high;

9. In the single mode, the glass can be intelligently accelerated at the inlet and outlet ends to save the processing cycle time;

10. Automatic centering bracket, automatically centering according to the opening and closing size, so as to smoothly convey the glass;

11. Margin detection function, which is used to detect whether the glass sent in exceeds the set standard margin in real time. If the glass exceeds the set standard margin, the speed will be reduced according to the speed set by the user, so as to ensure the safety of glass processing.

12. System software such as ERP can be docked, matching and docking can be carried out by identifying two-dimensional codes or bar codes, and automatic marking function can also be connected.

Description of product technical parameter

Main Product Details

|

|

Width adjusting mechanism adopts servo drive, which makes drive more stable and faster. The speed of opening & closing is up to 8m/min, which is in high accuracy and good repositioning. |

|

|

The opening & closing uses high precision and large lead double ball screw and linear guide rail. To ensure the accuracy of glass processing size. |

|

|

Emergency switch and air plug. |

|

|

The upper part of body adopts rectangular steel tube. The bottom frame is made of shaft rib structure, which greatly improve the rigidity and torque resistance and reduce the deformation of the box body. |

|

|

The base adopt the beam type structure, all uses the rectangular steel pipe, high stiffness and strength, good stability. |

|

|

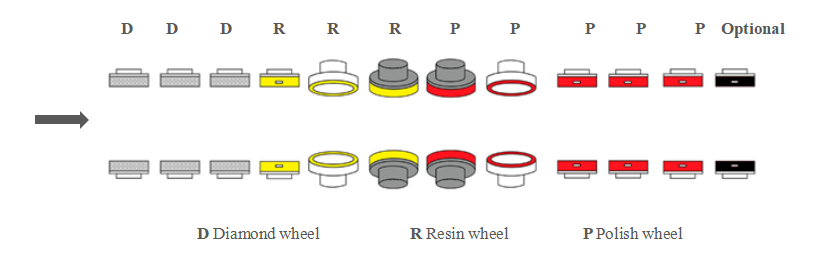

All grinding wheels adopt domestic top and international brands. |

|

|

Automatic center bracket. It is driven by steel wire and opened and closed together with the moveable side without manual adjustment, so that the center bracket can always be kept in the best supporting position. |

|

|

Polishing pneumatic compensation, without manual adjustment. The air pressure is used to automatically adjust the feed rate of the polishing grinding wheel, which effectively reduces the wear of the grinding wheel, and increasing the life of the grinding wheel. |

Our friendly team would love to hear from you!