Main components and configuration

|

No. |

Parts Name |

Brand |

|

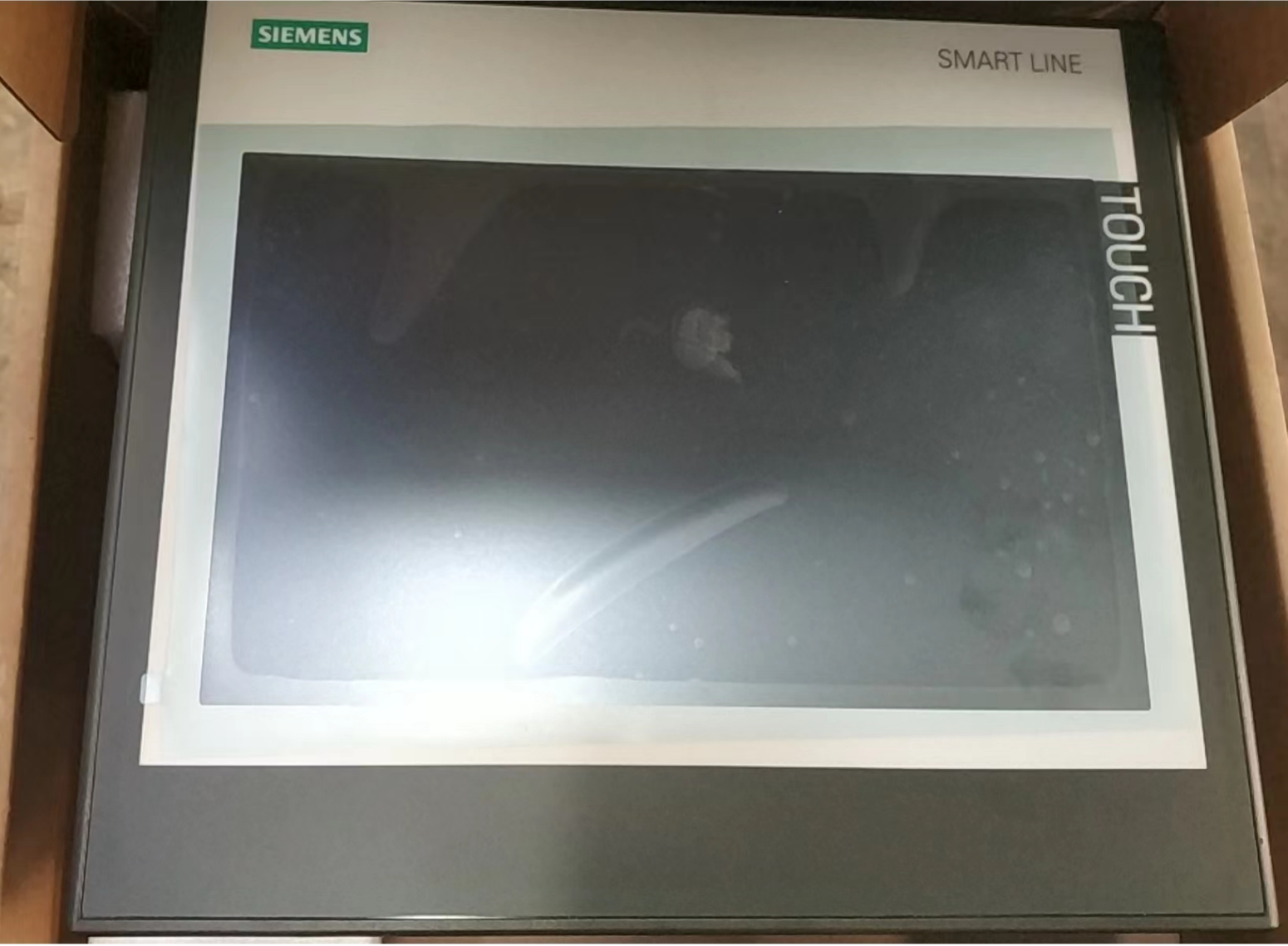

1 |

Low-voltage electrical apparatus |

Siemens, Germany |

|

2 |

PLC |

Siemens , Germany |

|

3 |

Servo motor and driver |

Siemens, Germany |

|

4 |

Button |

Schneider, France |

|

5 |

Proximity switch |

Schneider, France |

|

6 |

Relay |

Panasonic, Japan |

|

7 |

Air pipe(PU pipe) |

Morita, Japan |

|

8 |

Inverter |

Taiwan, Delta |

|

9 |

cylinder |

Taiwan·AirTAC/Sino-Italy Joint Venture··Yiri |

|

10 |

Solenoid valve |

Taiwan·AirTAC |

|

11 |

Oil water separator (filter) |

Taiwan·AirTAC |

|

12 |

ball screw |

Taiwan·PMI |

|

13 |

Linear guide rail |

Taiwan·PMI/HIWIN |

|

14 |

Temperature control meter |

Hongkong·Yudian |

|

15 |

spindle |

Shenzhen·Shenyi |

Feature of upvc window machine

1. Used for automatically realizing the welding and cleaning of frame or sash, composed of welding unit, transfer unit, manipulator and corner cleaning unit, etc.

2. Welding double layers for 2 unit one time.

3. The cleaning has 4 heads, automatic transfer the window and cleaning 2 corner one time.

4. Imported computer control system, with high reliability.

5 Production ability between main units matched each other.

6 Automatically program and select processing programs.

7. Apply to high grade and mass windows production.

8. Seamless and non-seamless function both.

9. Automatic welding and delivery to cleaning, auto cleaning and auto feed out.

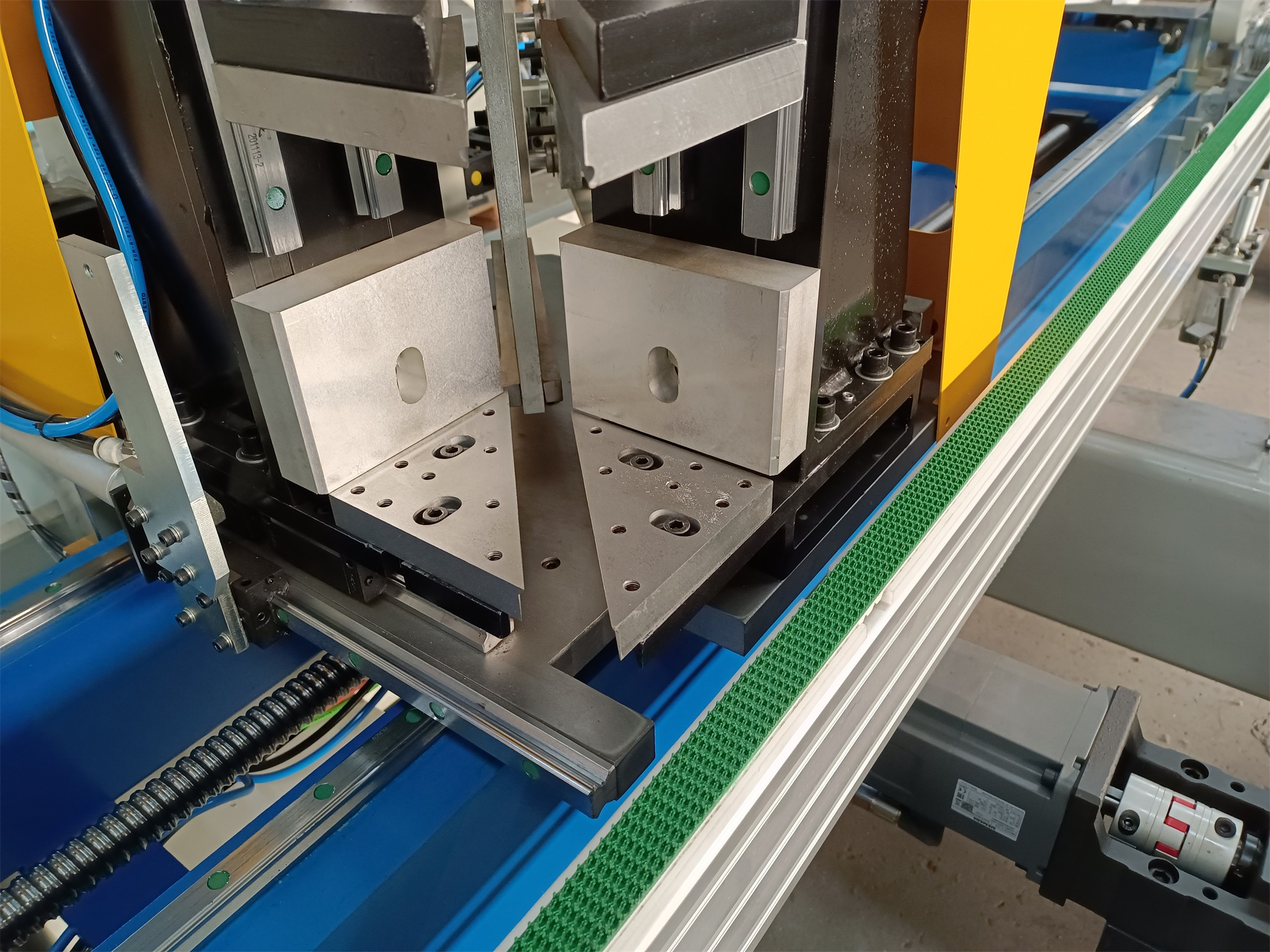

Welding Unit

1. Horizontal structure arrangement for the stable running.

2. Imported computer drive system ensured its high stability.

3. Size error compensation is available and high accuracy.

4. Special locating system and impaction device ensured its size precision.

5. Strengthen the corner welding and achieve good corner cleaning effect.

6. Supporter with proper design keeps the running stable.

7. Auto profile discharging device.

8.double layers for 2 unit one time

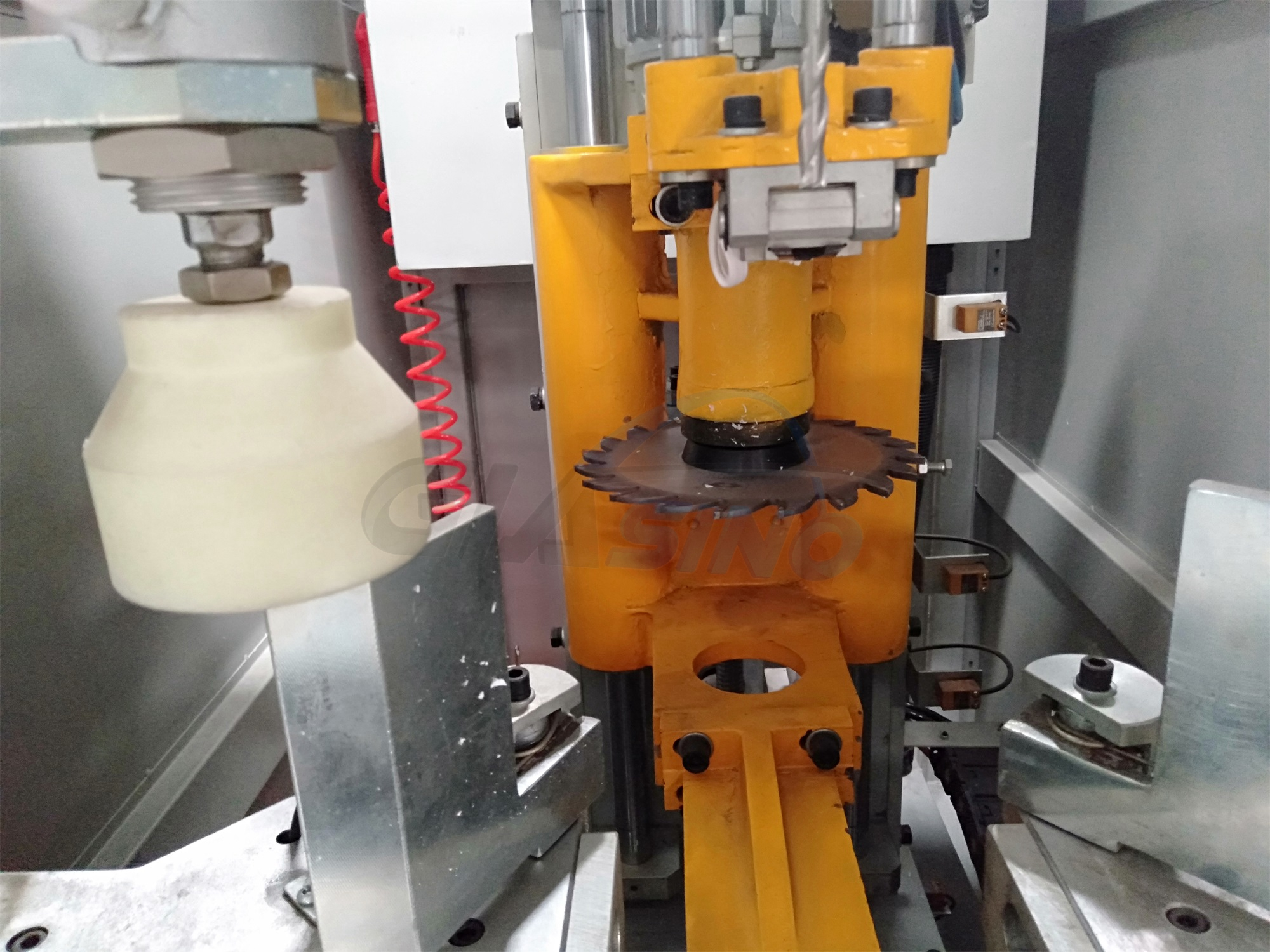

Cleaning Unit

1. Eight groups of different cutters can achieve the cleaning of corner welding.

2. High processing efficiency for adopting four-axis servo-drive system.

3. Imported computer system and drive system ensured its high reliability.

4. Cutters with unneeded change can process more than one hundred profiles.

5. Error compensation between arc and beeline is possible and good cleaning appearance given.

6.4 heads cleaning.

Transfer Unit & Manipulator

1. Transfer unit: used for automatically conveying the frame or sash after welding.

2. Manipulator: used for transferring the frame or sash to the precise position.

3. No labor needed in the transfer.

Packaging & Delivery

1, plastic stretch film coating;

2, steel pallet and plywood case package;

3, LCL or FCL by sea transportation;

Main technical parameters

|

No. |

Name |

Parameters |

|

1 |

Voltage |

AC380V/50HZ Three-phase four-wire |

|

2 |

Working pressure |

0.6~0.8MPa |

|

3 |

Air consumption |

100L/min |

|

4 |

Working environment |

CNC Controller:-5℃~60℃ LCD screen:0℃~60℃ Pneumatic Components:-5℃~70℃ |

|

5 |

Total Power |

Total Power:15KW Spindle motor power:0.75KW×3 Conveying motor power:0.37KW×3 Welding unit:1KW×1+0.75KW×2 Corner cleaning unit:1KW×2+0.4KW×1 Heating plate power:1.5KW×4(AC220V) |

|

6 |

Spindle speed of disc milling cutter |

0~12000r/min(frequency control) |

|

7 |

Spindle speed of end mill |

0~24000r/min(frequency control) |

|

8 |

Specification of right angle drill and milling cutter |

∮6×∮7×80(diameter × shank diameter × length) |

|

9 |

End mill specifications |

∮6×∮7×100(diameter×shank diameter × length) |

|

10 |

Welding height |

30~130mm |

|

11 |

Welding width |

30~120mm |

|

12 |

Welding precision |

Length、Width≤2mm;diagonal≤2.5mm |

|

13 |

Welding range |

400×450mm~2400×3000mm |

|

14 |

Cleaning Width |

20~120mm |

|

15 |

Cleaning Height |

30~130mm |

|

16 |

Overall dimension (L × w × h) |

About 14500×5500×2000mm Welding unit:3700mm Corner cleaning unit:3000mm Conveying unit:3000mm+2500mm |

|

17 |

Weight |

Total Weight:4000Kg Welding unit:2600Kg Corner cleaning unit:800Kg Conveying unit:300Kg+130kg |

More Pictures of machine

|

|

|

|

|

|

|

|

Our friendly team would love to hear from you!