1. Function

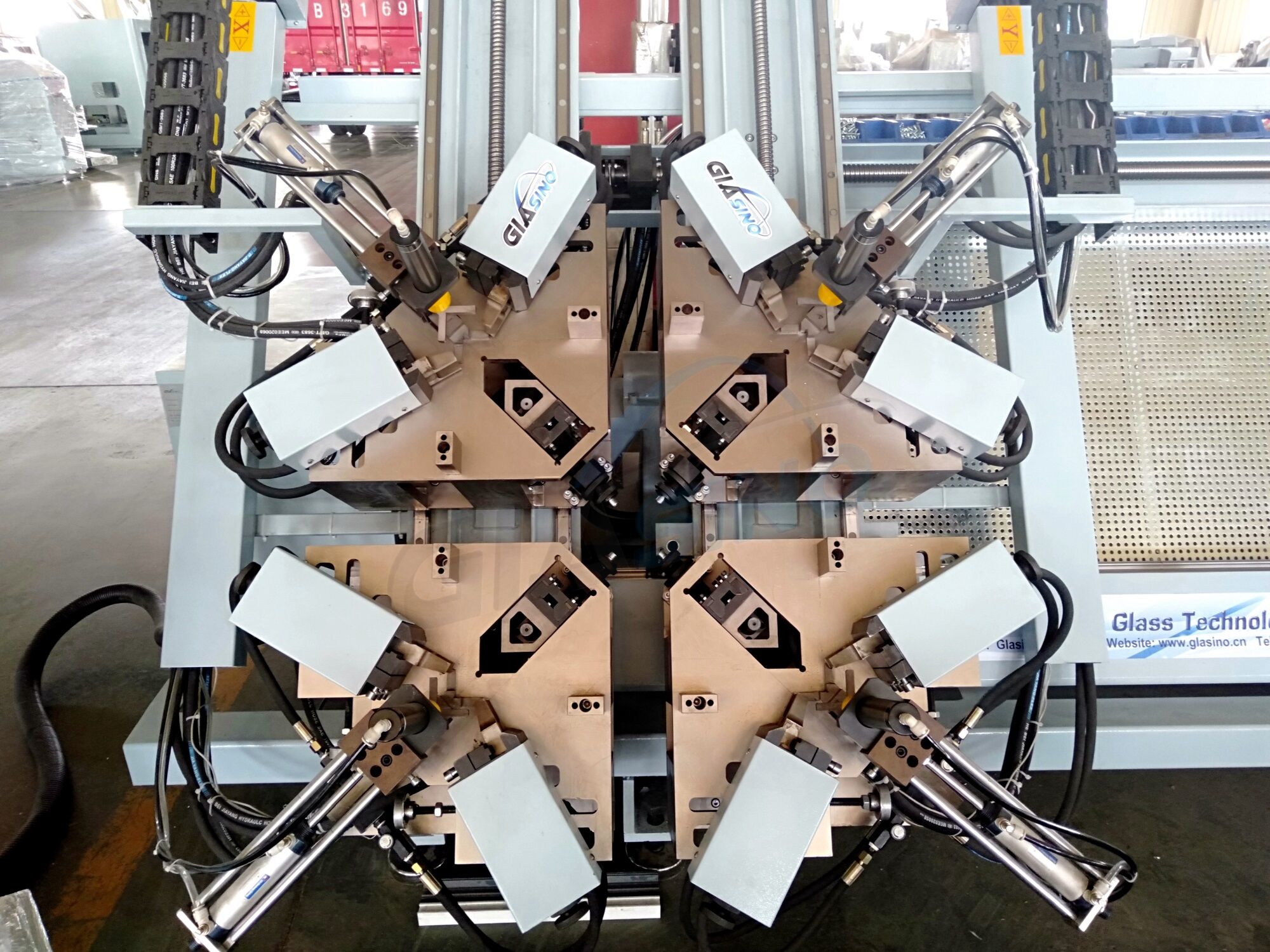

Used for aluminum window&door crimping

One frame crimping at the same time

2. Working principle

1) Input the size into computer though the display

2) The machine start to work to set position

3) Install the profile

4) Press auto-run button, the machine will finish crimping work automatically

3. Characteristic

The control system has position control and momental feedback function for preventing location error

Imported servo system, self-brake device for making sure high precision crimping and accurate crimping position

Dual enlarge location block makes stable location

High-low pressure dual feeding for improving the synchronism of the tooling

4. Key Points

The crimping process is controlled by CNC system and software. The machine moves according to the set size. But the actual size may be a little different from the set size (eg. 0.3mm more or less). The crimped frame may be out of shape and the machine may be distorted if the actual size is bigger than the set size. On the contrary, the four crimped corners of the frame may have seam if the actual size is smaller than the set size.

This CNC machine can conquer the above problems under the following three working status:

1) When the actual size is the same with the set size, the machine moves to the set size and finishes crimping work. Under this case, the crimped frame size is the same with the set size.

2) When the actual size is larger than the set size, the machine moves according to the set size. But when it meets resistance which reaches to a certain moment (the moment can be set in advance), the moving stops automatically and then crimping is processed. Under this case, the crimped frame size is bigger than the set size. But it is the same with the actual size.

3) When the actual size is smaller than the set size, the machine moves according to the set size. When it moves to the set size, the moving will continue till it meets resistance which reaches to a certain moment and then crimping is processed. Under this case, the crimped frame size is smaller than the set size. But it is the same with the actual size.

5. Technical parameter

|

Power supply |

Made to order, please confirm your voltage |

|

Hydraulic gearbox motor power |

7.5KW |

|

Rate oil cylinder pressure |

15Mpa |

|

Oil tank capacity |

40L |

|

Air pressure |

0.5~0.8Mpa |

|

Air consumption |

60L/min |

|

Crimping pressure |

12Mpa |

|

Processing profile height |

Max. 90mm |

|

Travel size for crimping cylinder |

85mm |

|

Adjust range of main locating plate |

54mm |

|

Min frame size |

480*480mm(door frame), 550x550mm(door leaf frame) |

|

Max frame size |

2200*3000 mm |

|

Dimension |

5100*2200*2660mm |

|

Weight |

About 2500kg |

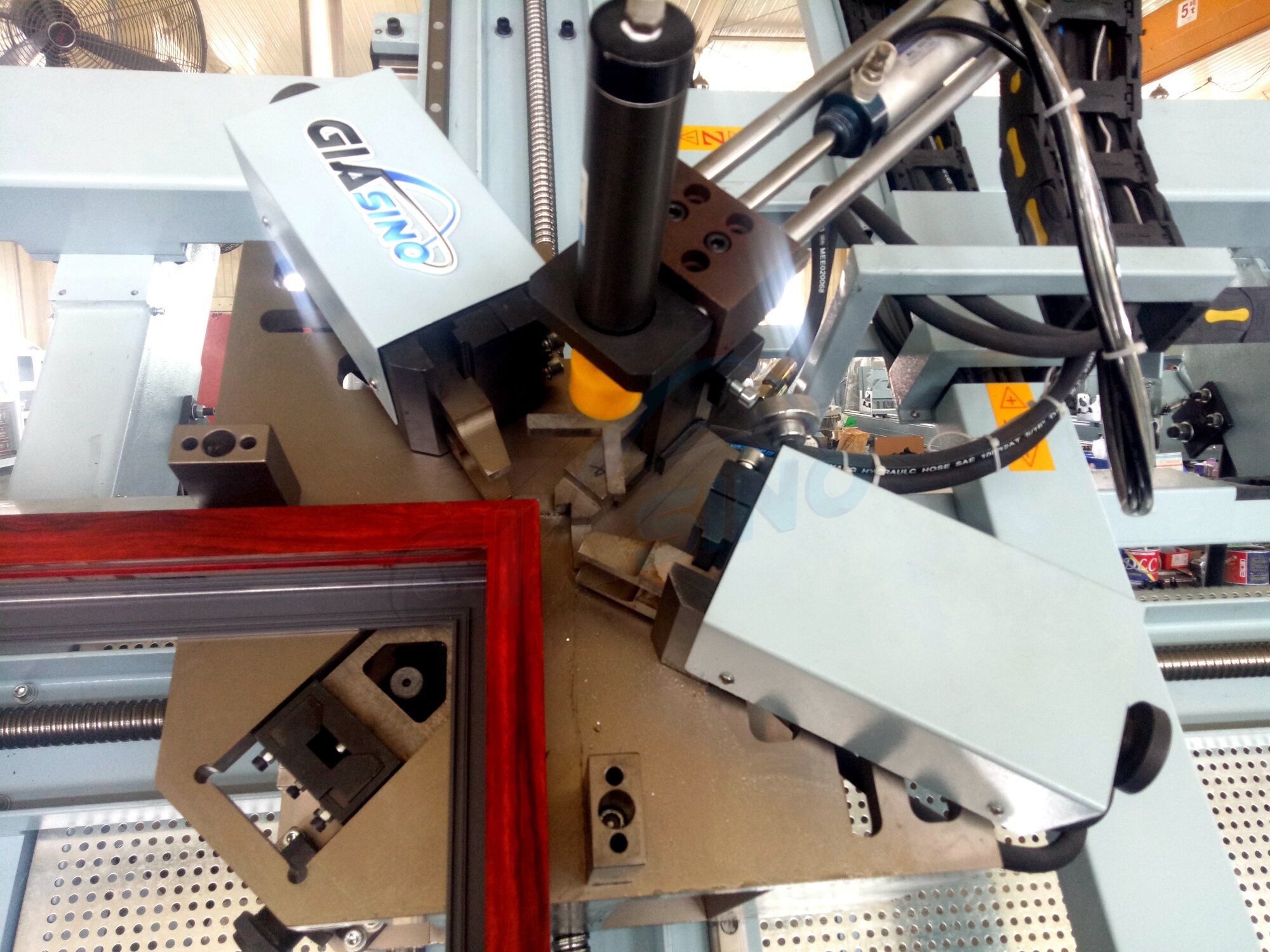

Pictures:

Our friendly team would love to hear from you!