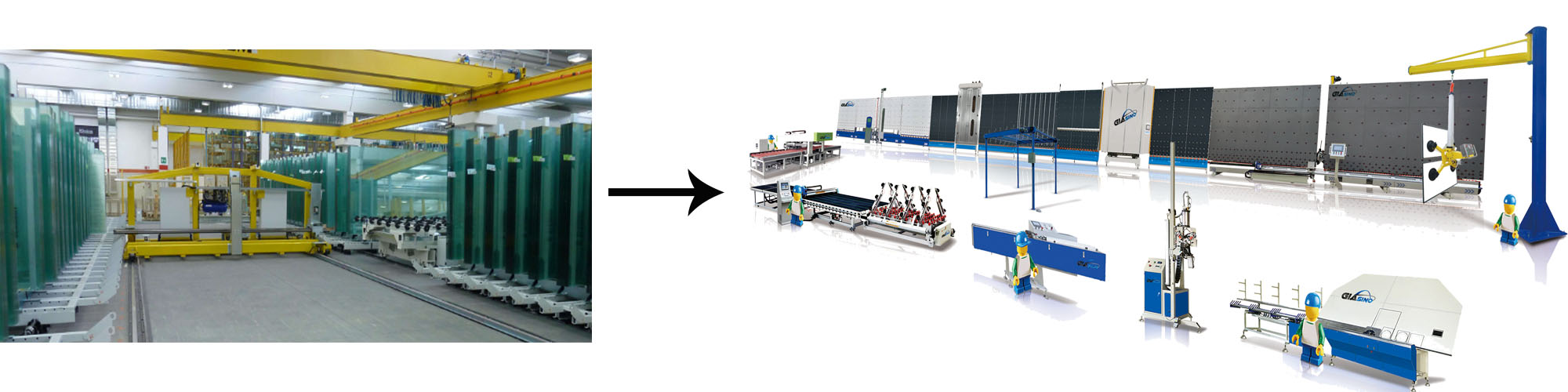

Product Description:

Equipment Features:

1. PLC control touch screen human-machine interface. 2. Automatic identification of coated glass and LOW-E glass film layer. 3. The application of imported vacuum generator and suction cup make better glass catching effect. 4. Three pairs of glass cleaning hairbrushes rotation speed can be driven by frequency conversation. 5. Big small sized and three layer hallow glass can be produced according to customer requirements. 6. Digital controlled assembling line to save production time and improve efficiency. 7. The production panel has been processed with plastic spraying to achieve beautiful appearance and durable service life. 8. Cleaning machine is made with stainless steel and resistance material. 9. All electric appliance are selected from famous international brand. 10. The press section can be pushed to 450mm with big stroke to make it convenience for maintenance. (Optional) 11. When for exterior conjunction the plate press adopts central location way. 12. Free alternative between interior and exterior cunjunction. 13. The press section adopts opening-door style to convenient overhaul and maintenance.

2. Whole machine adopt man-machine touch screen interface, with memory function .

3.After coating sealant ,the glass edge and corner is full without air bubbles , smooth surface, no need to pare the corner .

4. Using two sets of independent sealant supply system , two kinds of sealants switch fast ,in one-button operation easily (Model II),save time to change sealant.

5.The width of machine is 1.4m ,small floor area, save space .

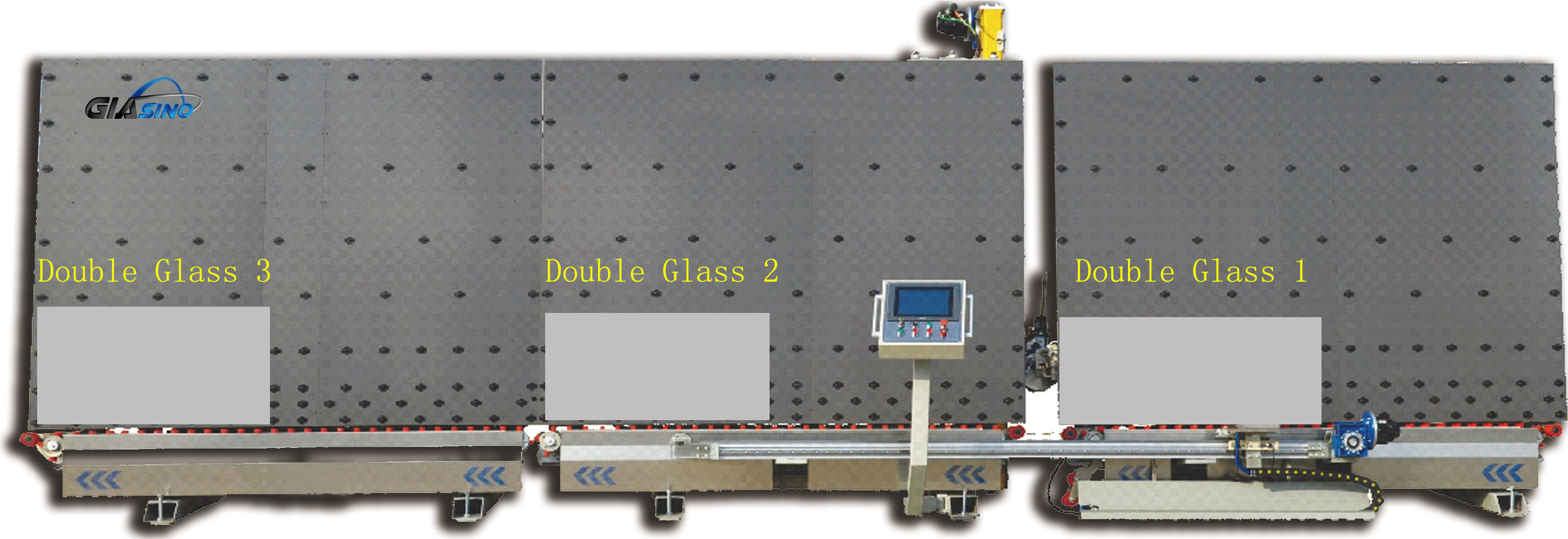

6. The sections is one production line, it can prestore three pcs glass to improve the efficiency effectively, small glass transport with short section .big glass transport with long section ,save energy .

7.The smallest insulating glass size can be processed is 300*300mm

8.Equipped with anti blocking device in the mixer, easy to clean

9. Servo control system adopts world famous brand (Japan YASKAWA ), the performance is stable ,

counting speed is fast ,sealant output with high precision ,surface with high smoothness .

10. Shaft transmission to make the glass being transferred smoothly with accurate positioning.

11. Special V type transmission belt to avoid the sealant sticking on the belt, ensure the glass edge clean , V type Block is changeable .

12. The spare parts are produced with high standardization and high precision, ensure the machine can

be used with long-term stability

13.Suitable for triple glazing ,seal the two cavities in one time

14.Conveying wheel on backboard adopts embedded wheel ,to make sure the glass be transported smoothly

15.Equipped with high speed positioning function ,glass can be located accurately when transport fast .

16.Touch screen adopt ethernet communication, sensitive operation, suitable for popular operation .

17 High pressure non-return valve to make the washing speed faster,save sealant and avoid blocking

18 All low-voltage appliance adopt France Schneider to make the performance stable.

19 .Servo transformer with long life service ,low power consumption .

20 Sealant pressure real- time display on touch screen convenient to adjust.

21.Keep machine service and upgraded timely with our own R&D departments

22 20 years experience in extruding systems to make the system more stable .

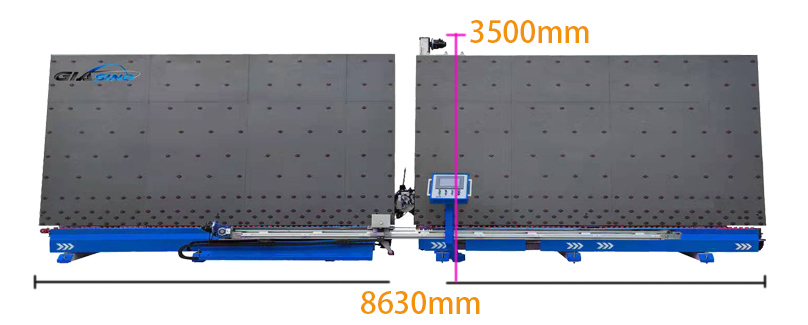

Technical parameter:

Power: 380V 50HZ 3 phases

Input power: 9KW

Air source: 0.6-0.8Mpa

Max. IGU size: 2500*4000mm

Min. IGU size: 300*300mm

Glass thickness: 12-56mm

Work speed: 5-40m/min

Overall dimensions: 8600*1400*3500mm

Packing & Delivery

Company Profile

Jinan Glasino Machinery Co.,Ltd founded in 2003, is the high-tech enterprises specializing in the production of Glass tempering furnace CNC glass cutting machine, insulating glass machine, curtain wall glass machine, market share ranks first in the same line. Main products are: Laminated glass cutting machine, Automatic glass Cutting line, Multifunctional glass cutting machine, Insulating glass production line, Automatic insulating glass CNC sealing machine, Aluminum spacer bending machine, Desiccant filling machine etc, full set processing machines for insulating glass. We have passed European CE certificate, Switzerland SGS certificate ,ISO 9001: 2008 quality control system, win good reputation from domestic and international customers. Outstanding quality is the basis of brand. Satisfying service is the guarantee or brand. Perpetual innovation is the soul of brand. Glasino people will continue making efforts and persist in taking the quality as the life of the enterprise. Continuously improve the production management level, research and develop more advanced technology to meet the needs of the market. Glasino will work with you to create a brilliant future.

Our friendly team would love to hear from you!