Characteristics:

Characteristics:

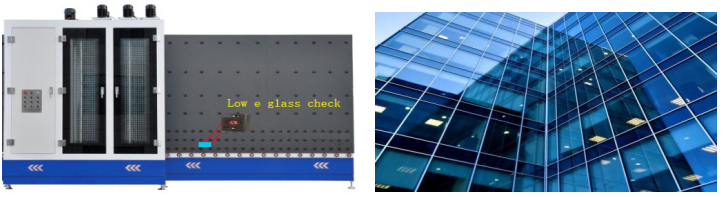

Automatic identification of LOW-E and coated glass, automatic alarm of glass anti-releas.

2. The washing box is equipped with Seven motors, three pairs of brushes and one-to-one transmission between brushes and motors.

3. The washing box is thickened with stainless steel, and the base is designed with Double-layer hollow-out to avoid water storage and improve the service life of bearings.

4. The Stainless steel pipe is used to connect the spray pipe of the cleaning box with the intake pipe to prevent ageing.

5. Washing box bearings have three seals: upper and lower oil seals and water-proof shield to prevent water and glass dust from entering the bearings.

6. The universal nozzle of the cleaning box can be cleaned thoroughly without dead angle. Fan-shaped sprinkle

7. Coarsening stainless steel chain is used for Washing box.

8. The washing box features Octopus wind knife and three-stage air intake to ensure the cleaning effect of large and small glass.

9. Wind knife special baffle structure, strong wind, uniform air supply.

10. Machine automatic identification of glass thickness at windblade position is the best way to keep the distance of blowing from the glass.

11. The fan power is 15KW, strong and powerful.

12. The bellows are equipped with sound absorption devices to reduce noise pollution.

13. When the glass stays at the position of the windshield knife, the tuyere will automatically close to prevent water stains.

14. Water tank with inclined angle, horizontal drainage outlet, sediment removal thoroughly.

15. The water tank is equipped with tugboats of different diameters, which are easy to change water, with built-in baffles, and can be separated by roughing and scrubbing.

16. The water tank is equipped with thick stainless steel drainage pipe and automatic overflow function.

17. There is a drop in the hose at the connection of the water tank motor and equipment to prevent the freezing phenomenon of water storage in winter.

18. and 03 are equipped with speed-up photoelectric switch to improve production efficiency.

19. Hand-operated aluminium bar positioning in detection section, easy to adjust and accurate positioning.

20. Special speed-up device in the detection section. The outer beam can perceive the glass height in advance and save time.

21. Opening device of special glass bracket in outer closing section to prevent misoperation of glass.

22. The precise positioning device with three glasses and two cavities is carefully designed in the external segment.

23. External closing section is extruded by double cylinders, and the joint is stable and accurate.

24. Plate pressing adopts large stroke, which is convenient for overhaul.

25. Strengthened ribs of plate pressing are uniformly distributed in mesh shape, strong and uniform in force. The phenomenon of bell mouth and broken glass in glass during plate pressing is prevented.

26. Hydraulic transmission is adopted in the plate pressing section, which is stable, flexible and powerful.

27. Plate pressure shield is opened by one key, which is convenient for maintenance and high efficiency

28. All chains are equipped with protective covers to ensure safety and hygiene.

29. German Siemens 7 sets of frequency converters, high precision, fast speed, long life.

30. German Siemens Low Voltage Electrical Appliances, high-end precision.

31. German Siemens PLC, original, high precision.

32. French Schneider relay, stable and safe.

33. The electric cabinet is equipped with air plug, which is convenient to install, safe and efficient.

34. The colour difference between intake and outlet pipes is standardized and efficient.

35. Distribution boxes are equipped with detection lights for easy maintenance.

36. Ethernet transmission, fast speed, high accuracy.

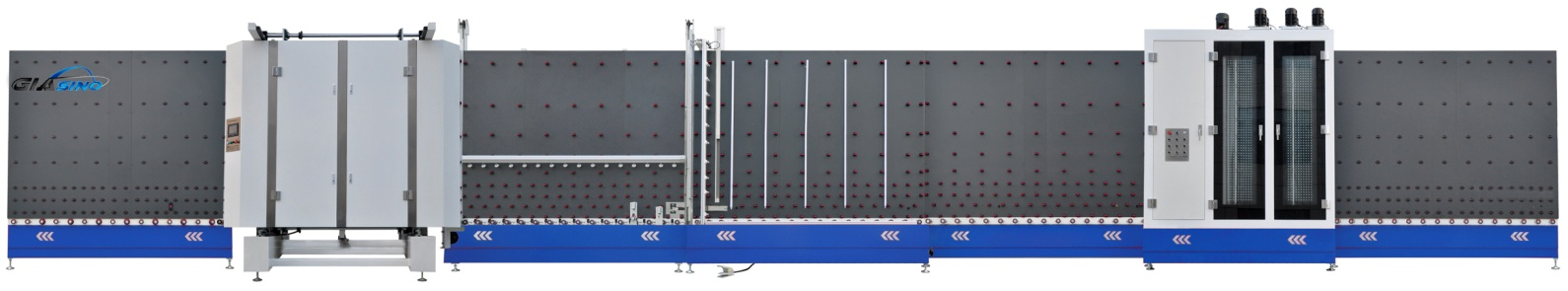

Technical parameter

| Parameter | LB2025 | LB2030 | LB2536 |

| Power Supply | 380v 50Hz | 380v 50Hz | 380v 50Hz |

| power | 30kw | 30kw | 34.0kw |

| Max size | 2000×2500mm | 2000×3000mm | 2500×3600mm |

| Min size | 300×500mm | 300×500mm | 300×500mm |

| Glass thickness | 3—12mm | 3—12mm | 3—12mm |

| Transport speed | 8—45m/min | 8—45m/min | 8—45m/min |

| Weight | 5500kg | 6000kg | 7000kg |

| Overall dimension | 19000×1800×3100mm | 22000×1800×3100mm | 26000×1800×3600mm |

Our friendly team would love to hear from you!