Whilst breaking a glass, ungenuine or otherwise. If you do, then you are aware of how easy they can shatter. Glass is fragile, very sensitive and can crack easily. Buuut that sounds terrible but look on the bright side, we can make glass much stronger! It is done using a machine known as a glass tempering machine which makes normal glasses even stronger.

What does this machine do that it is so amazing? It first makes the glass super hot. This heating step is critical as it readies the glass for finalization. Then the glass is rapidly cooled again, but in a special way after it becomes very hot. So the glass is called as "tempered" glass & its quality become high, strong and sturdy so that it can resist higher compression forces before breaking.

We accomplish this by utilizing something known as laminated glass. Laminated glass is specially treated with a thin plastic film that it sandwiched between two layers of regular glass. It has this design that makes it a lot tougher to break. Even if does shatter, the plastic layer hold all of it together making sure nothing flies around and leaves a huge mess.

One way to prevent breaking of glass is the use of thick glasses. Blocks of thicker glass are very strong and difficult to break, even with something heavy or hard hitting against it. In locations with risk of glass breaking, such as crowded buildings or vehicles same extra strength is tougher.

But if it does break, it shatters into small rounded pieces rather than sharp shards. These are much gentler, as sharp sections can be dangerous. The rounded pieces of the greater calvins make there to be much lower risk in someone getting smaller_buff(person) hurt. This is the case especially around where people tend to be such as homes, schools and offices.

Now the glass heated and quickly cooled with special quenching system. This rapid cooling process corresponds to the fact that this glass is much more resistant and stronger compared to normal glass. It also imbibes a kind of layer of stress between the glass which allows it to stand strong facing pressure or load. The additional strength is what makes tempered glass unique and gives it an aspect of dependability that simply cannot be matched by other types.

This has been a major revolution for the glass industry, most likely lowering barriers to using strong glass in other products. Toughened glass has come a long way, starting from the windows and even in our phones screen we now unknowingly depend on toughened glass for various reasons that kept evolving with time.

According to the glass tempering machine according to the current market, the factory alters the production plan to accommodate the fluctuating demand of the market and to maintain an edge in competition. Produce flexible lines of production, using information technology, to meet market demand. Modify production plans according to timing.

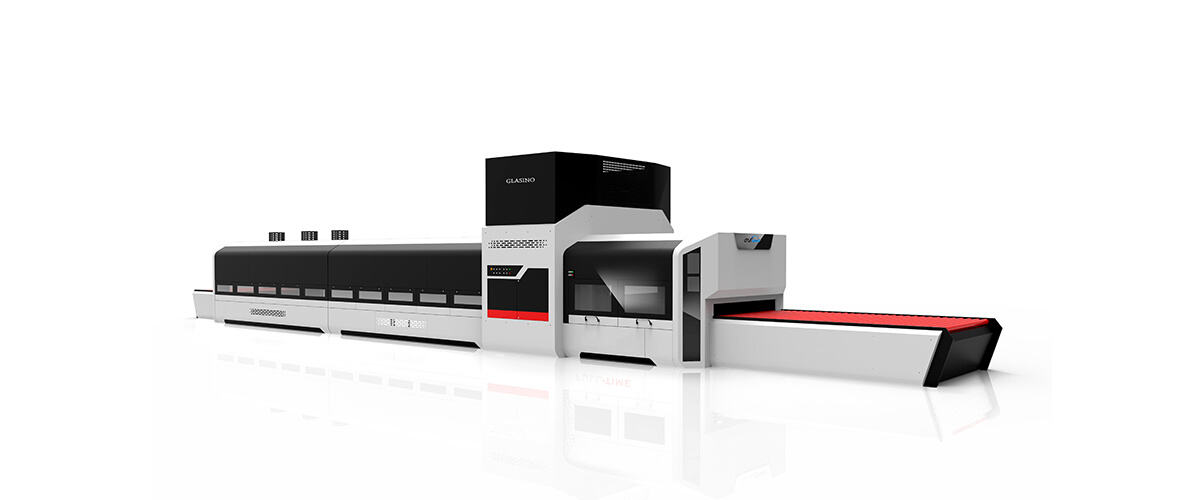

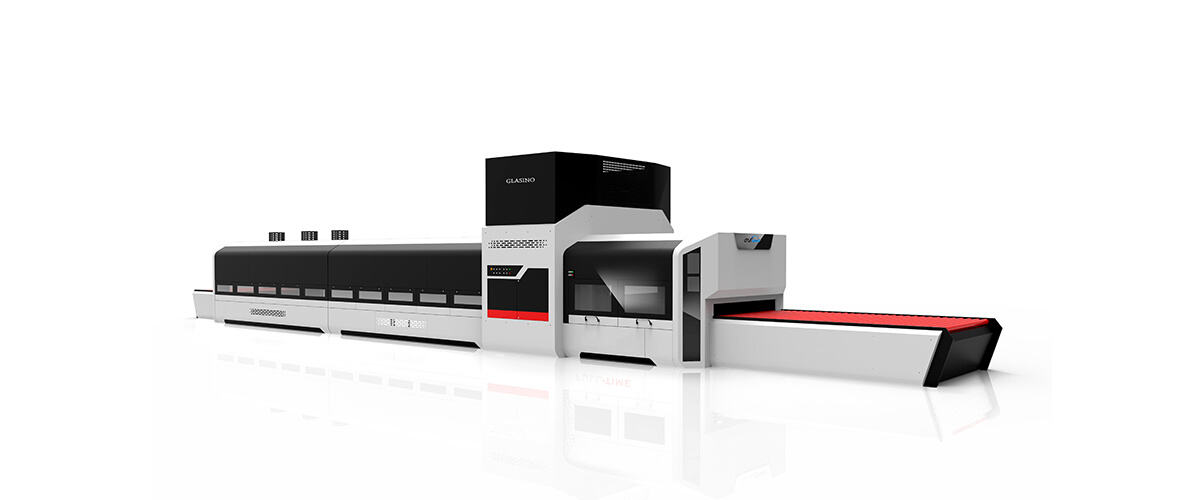

The production facility reaps the benefits of economies of scale Through the introduction of automated production and modern equipment manual processes can be cut down High-efficiency equipment also can produce at a glass tempering machine that improves the efficiency of production and speed

To decrease the glass tempering machine of products that are defective, and to improve customer satisfaction, strict quality inspections are conducted. A solid quality management system to attain continuous quality management. Improvements in inspection and testing techniques

The focus of the factory is on technological advancement in the production process Develop new ways to use glass tempering machine technologies and develop new ones Enhance the production techniques Stay competitive in the market