Brief Introduction:

1.Siemens PLC control, Eview touch screen

2.Airtac pneumatic parts

3.Omron servo motor for feeding and bending

4.Error after bending ±0.3

5.Four spacer selective storage areas for four kinds of different lengths of spacers

6.The machine will keep away the connect point, arch point during bending and cutting

7.Manual operation is available for easy maintenance

8.Different shapes of alu-spacer bending is available, such as triangle, rectangle, pentagon, hexagon and arch shape

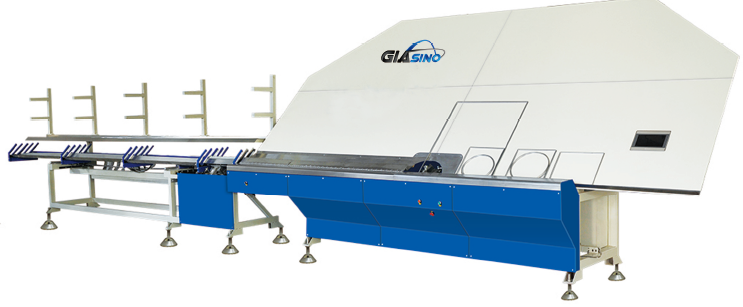

Technical Parameter:

1.Spacer width: 6~20mm

2.Minimum spacer frame size: 200×250mm

3.Maximum spacer frame size: 2500×2500mm

4.Bending speed: less than 30s/frame (1000*1000mm)

5.Air pressure: 0.6Mpa

6.Overall dimensions: 10000×2100×2600mm(L×W×H)

Features:

1. Rotating arm, easy to operate

2. Bending heads adjustable according to width of aluminum spacer

3. Double stations for improving work efficiency(three or four can do it)

4. Automatic feeding and cutting of aluminum spacer

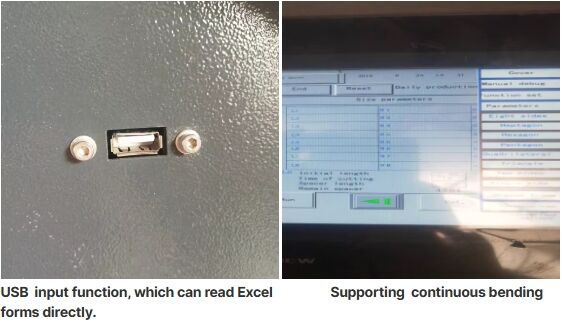

5. Shape bending a, support continuous bending

6.USB input function, which can read Excel forms directly

7. All stainless steel panels

8. Automatic error compensation function, higher accuracy

9. Code spraying function of aluminum spacer

10. Low-voltage appliances: Schneider, France;

PLC: Germany Siemens;

Air valve: Taiwan AirTac

11. Real-time monitoring of aluminum spacer position

12. Turn the tool head ahead of time to ensure complete cutting

13. Folding stainless steel, SWISS Spacer and other warm edge, aluminum spacer.

| Name | Brand | Remark |

| PLC | Siemens | Germany |

| Servo Motor | Omron | Japan |

| Relay | Muller | Germany |

| Touch screen | WEIN-VIEW | Taiwan |

| Proximity switch | Omron | Japan |

| Microswitch | Omron | Japan |

Machine Detail Picture Reference

Company Profile

Our friendly team would love to hear from you!