Machine introduction:

1. Applicable for drilling holes ,milling groove ,circular hole,irregular-shaped and keyhole and plane engraving of aluminum profile.

2. It Adopts MCGS CNC system,which makes sure smooth running of machine.

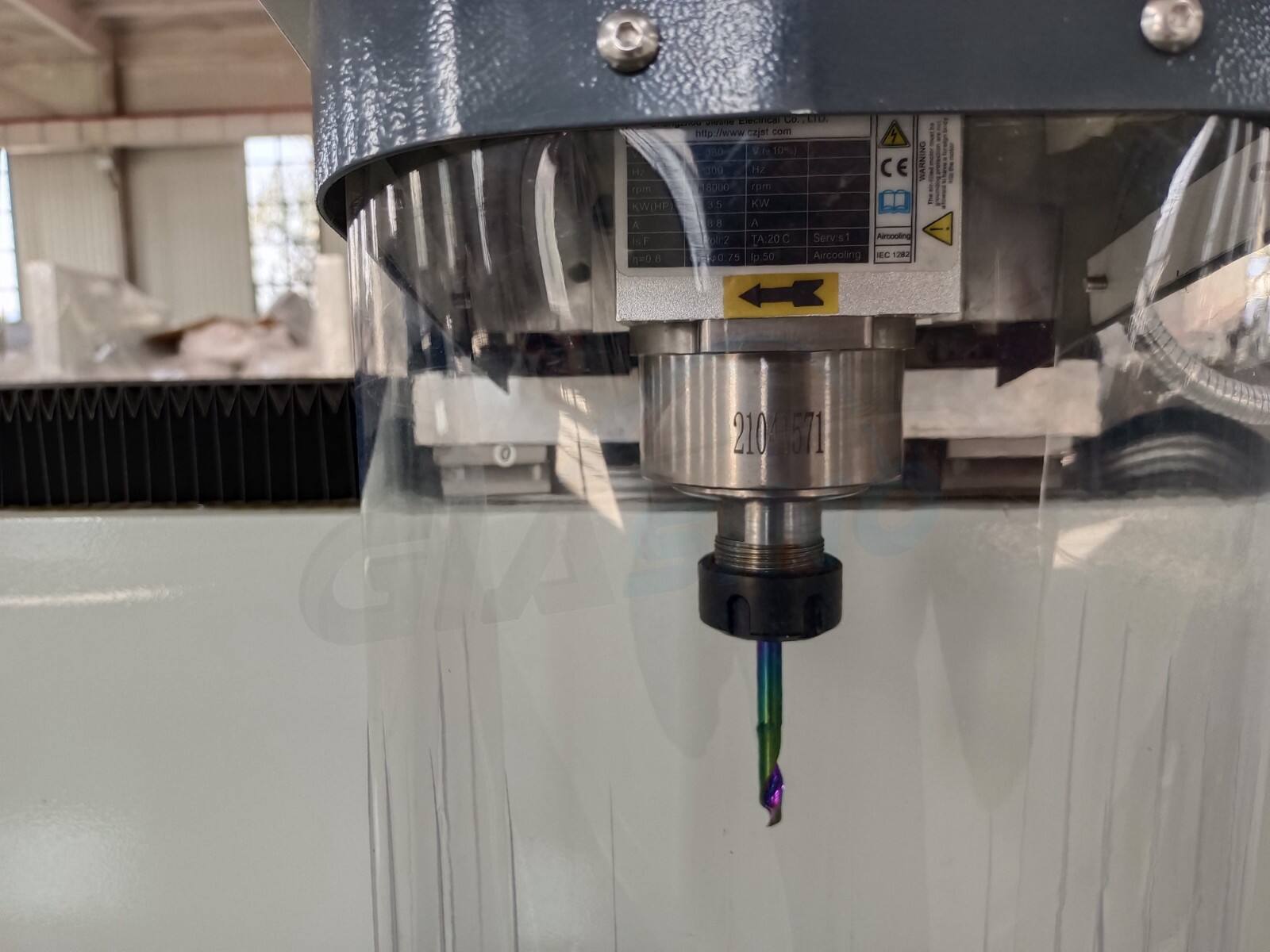

3. Electrical spindle is China brand air cooling 6.0KW, 18000r/min.

4. Imported Taiwan guide rail, sliding block, X axis adopt high precision oblique gear and rack driving. Y and Z axis adopts high precision ball screw drive. The drive is stable, so can improve the precision of whole machine .

5. CAD-CAM Programming software can automatically convert G code,you can drawing any holes on computer.

6.Worktable can be rotated to 180° (-90° -0°- +90°), Clamping profile one time, three sides processing. it can process deep and special-shaped holes through workbench;high efficiency and precision.

7.Adopt manual oil supply system, blades adopt system control spray cooling device.

8.The main electrical parts: circuit breakers, AC contactor are all SCHNEIDER brand.

9.The main components adopt steel structure and they are all through aging treatment.

10.Effective processing range: 200mmx200mm. Length 3000mm.

Technical parameter:

| Model | ZXC-CNC-3000 |

| Working voltage | 380V 50HZ(please confirm the power) |

| Total Power | 12KW |

| Max rotary speed | 8000-18000r/min |

| X-axis Journey | 3200MM |

| Y-axis Journey | 500MM |

| Z-axis Journey | 350MM |

| Air Pressure | 0.6-0.8MPA |

| Air consumption | 100L/min |

| Spindle Power | 6.0KW |

| X-axis speed | 0-60M/min |

| Y-axis speed | 0-60M/min |

| Z-axis speed | 0-60M/min |

| Weight | About 1400KG |

Our friendly team would love to hear from you!