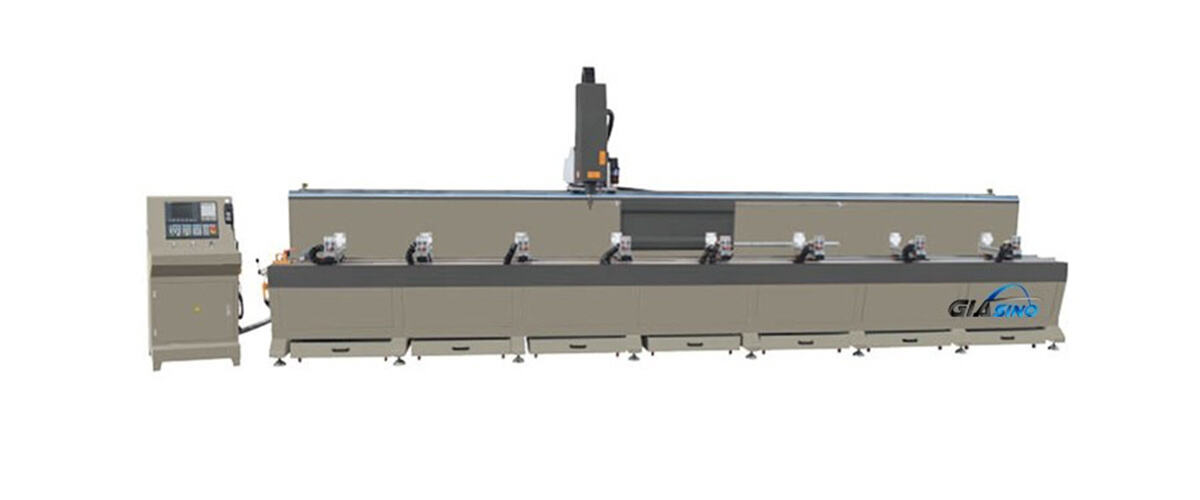

Features:

1.This machine is designed for processing round holes,slots,keyhole etc on aluminum profile,window-door and curtain wall industry,it is also suitable for processing milling,chamfering,engraving plane surface and other procedure.

2.Main spindle adopt air-cooling electric main axis from Italy,have the function of high precision,high safety and high reliable.

3.Adopt Germany control system.Have professional CAD-CAM programming software.It can transform processing code automatically,have the function of easy operation,high efficiency and lower labor intensity.

4.Imported guide rail,sliding block,X axis adopt high precision oblique gear and rack driving.Y and Z axis adopts high precision ball screw drive.The drive is stable,so can improve the precision of whole machine.

5.Inside blades storage can hold 6 sets blades,the handle is approved ISO 30 standards,it is very safety and reliable.

6.Adopt manual pump oil supply system,blades adopt system control system control spray cooling device.

7.The main electrical parts:circuit breakers,AC contactor are all SCHNEIDER brand.

8.The main components adopts steel structure and they are all through aging treatment.

Technical parameter:

| 3 Axis CNC Processing Center for Aluminum Profile | |||

| LCJG3-CNC-6000 | 1 | Power supply | 380V 50Hz |

| 2 | Air pressure | 0.5~0.8MPa | |

| 3 | Total power | 12kw | |

| 4 | Max rotary speed | 24000/min | |

| 5 | X-axis speed | 6000mm | |

| 6 | Y-axis speed | 500mm | |

| 7 | Z-axis speed | 350mm | |

| 8 | Y and Z axis speed | 1500mm/min | |

| 9 | Overall dimension | 7100 x 1600 x 2200mm | |

| 10 | Weight | 2360kg | |

More Details:

Our friendly team would love to hear from you!