GSXM371A Glass straight line beveling machine

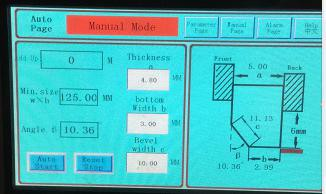

1.Using PLC to control glass processing thickness, angle and height.

2.Suitable for grinding flat glass with different bevel edge.

3.The coarse grinding, fine grinding and polishing can be finished at one time.

4.The front pressing plate can be adjusted by lifting system according to glass size.

5.The pressing plates are using with thicker steel plate, which make machine more stronger, transmit steadier and in higher working precision.

6.Working speed can be adjusted at will by continuously variable mechanism transmission, this make operation very easy.

TECHNICAL SPECIFICATIONS

|

voltage |

Power |

Bevel angle |

Max bevel width |

|

380v/50Hz |

22.7kw |

0°-35° |

40mm |

|

Glass thickness |

Feeding speed |

Min size |

Weight of machine |

|

3-19mm |

0.5-5m/min |

30x30mm |

3500kg |

|

Overall size(LxWxH) |

6800x1300x2500mm |

|

Machine configuration

1.Foundation, beams & bracket: cast steel, annealing treatment.

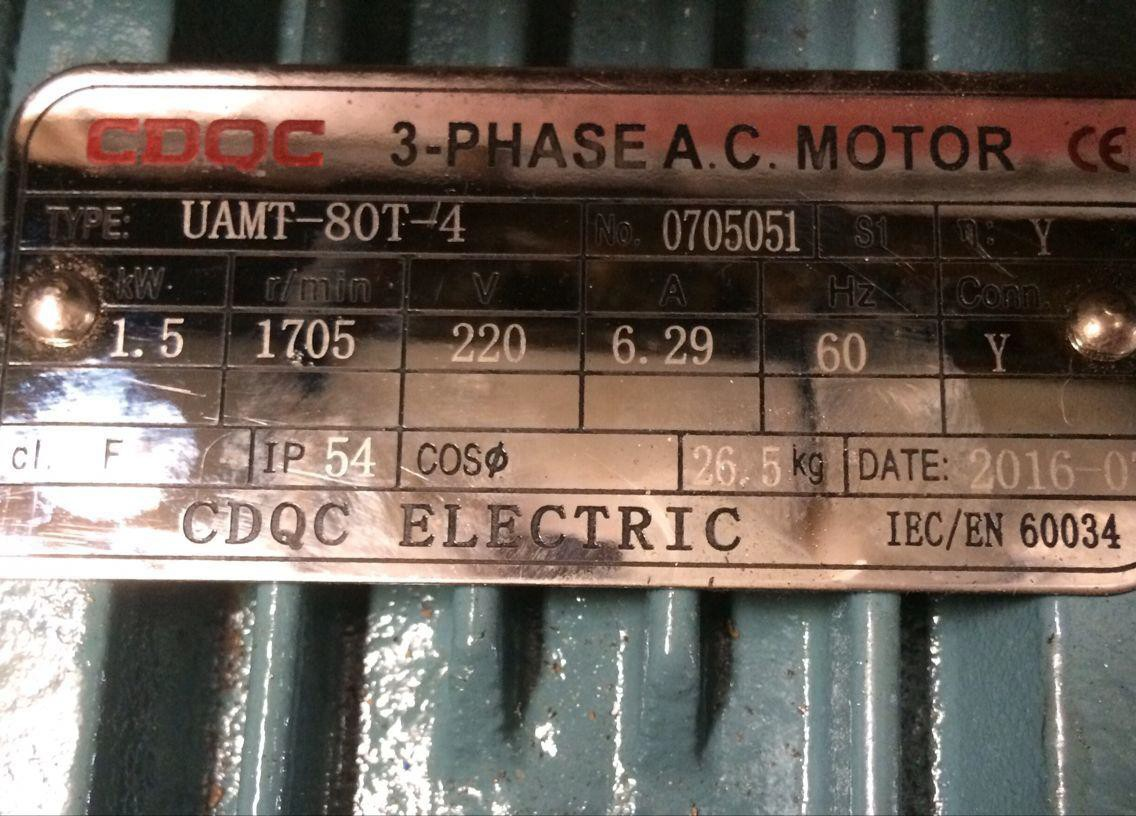

2. CDQC motors.

3. Mitsubishi PLC system.

4. France electrical components.

5. PU synchronous belt transmission chain.

6. Stainless steel water tanks ( cooling & polishing tank both).

7. 1kg Cerium oxide polishing powder.

8. Raw carbon treatment press plate.

MACHINE CONFIGURATION WITH PHOTOS:

1.Foundation, beams & bracket are heavy duty cast steel, annealing treatment. Stable, will never deformation and Ensure high process precision.

2.Use CNC grind machine grind beams, provide high process precision.

3.All the spindles are CDQC motors.

4.High quality stepless speed change motor. Working speed can adjut 0.5-5m/min.

5.Schneider electrical components, High quality, Neat wiring layout, ease of maintenance and management.

6.PLC/ Manual control system optional, make process more Faster, accurate, efficiency and easier.

Our friendly team would love to hear from you!